U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Presentations by the various hosts to the U.S. delegation included discussion on the process of innovation, commonly used evaluation techniques, specific innovative materials, and other findings. The following sections describe the scanning team's key findings during the study.

Over the past several years, a migration in process and specification has occurred in most of Europe. Many countries are transitioning from using methods-based specifications to developing and adopting more functional requirements for their construction materials. Functional specifications are similar to end-result specifications used in the United States, but they also incorporate elements of performance specifications. The objective of a functional specification is to ensure that the end product is constructed to meet the function for which it is intended (e.g., the noise level, smoothness, and safety that the public expects or demands). The use of these specifications and contracting methods has resulted in the introduction of more innovative materials, since as long as a material meets the specified function, it is deemed acceptable.

In fact, the definition of “superior materials” appears to be based more on functional requirements rather than cost. Demonstrated innovations commonly resulted in more functional but more costly solutions. In some cases, the higher costs could be offset by incentives from policy or legislative requirements. In other cases, additional initial costs could be justified when life-cycle (whole-life) costing was considered.

The future trend appears to be a requirement of functionality over time (performance specifications). A wearing course, for example, will be required not only to meet a maximum noise level, but also to maintain a specified level over a specified number of years.

In short, the process of materials selection is commonly driven by a risk-versus-reward assessment. While this assessment is not always formal, it includes a rational means to weigh the costs and benefits of using conventional-versus-innovative materials.

The formation of the EU has had a profound impact on most facets of government. By working to eliminate barriers to free trade, the EU is creating opportunities for vendors and owners to move together toward standardized functional specifications rather than conventional prescriptive specifications. To assist in this effort, the European Committee for Standardization (Comité Européen de Normalisation, or CEN) was established to coordinate and manage the specification standards.

While the CEN standardization process is moving forward, it is not without difficulty. As part of the harmonization process, each member country must debate the various details of its previously independent specifications. A further consideration is the differences that arise in definitions and language (the official language for the specifications is English, although French and German versions also will be approved for use). When asked if the EU standardization process leads to a more innovative environment, some countries responded that the process benefits industry (by encouraging cross-border competition, for example). Some individuals, however, believe that the CEN specifications may make them vulnerable to delivery of substandard materials.

In addition to the CEN, a second organization, the European Organisation for Technical Approvals (EOTA), provides a common testing and evaluation forum for products that do not have a standard specification. Additional information on the EOTA process will be researched during the implementation phase of this scan.

In summary, the development of the CEN specifications can be contrasted with AASHTO specifications. While AASHTO has produced guide specifications that States have the option to adopt or modify, the EU is in the process of combining current specifications into a common binding specification for use across Europe. It should be noted that within the CEN, quality classifications allow for varying thresholds and tolerances on the material test results.

All of the organizations the scanning team met with discussed the use of warranties and performance contracts as part of their everyday practice. The specific elements of these contracts varied, ranging from short-term (1-to-3-year) materials and workmanship warranties to long-term (more than 30-year) design-build-finance-operate (DBFO) contracts. While these types of contracts are common, highway agencies appeared to have varying levels of comfort with them. Some agencies appear more willing to relinquish control because they have seen an obvious increase in quality, while others appeared to be more cautious in their adoption.

While an increase in quality often resulted, innovation through the use of superior materials was not always realized merely because of a warranty mechanism. Their use was more common on longer-term warranties in which the contractor had more latitude in the materials and processes it could use. Where superior materials were used, the specifications were much more performance based. Some difficulty remains, however, in how to define the performance standard, including what to measure, how to measure it, and when it should be measured.

In addition to warranty contracts, maintenance contracts were also commonly used. These contracts resulted in privatization of the maintenance activities for a highway facility, and were normally accompanied by functional requirements. In fact, the momentum gained from the use of functional requirements for maintenance contracts has led to their use on conventional construction projects. Contractors were encouraged indirectly to develop their own management systems to track resources. More innovative companies typically had lower life-cycle costs, and thus could submit lower bids covering a longer time period.

Finally, the scanning team learned that contractor quality (and/or past performance) was sometimes considered in the award process, as was life-cycle costing and sustainability (environmental impacts). In some countries, contractor quality overshadowed cost and the low-bid process. These considerations led to innovative solutions for some contracts, including the use of superior materials.

The scanning team observed a variety of models for product evaluation and certification during its study. While most countries had well-established systems in place, officials stressed that European standardization was changing this, with EOTA serving as the coordinated organization for considering materials for which a standard does not exist.

In the United Kingdom, the Highways Agency (HA) uses an innovative process termed the Highway Authorities Product Approval Scheme (HAPAS). Administered under an independent certification agency, the British Board of Agrément (BBA), the HAPAS process involves working with the private sector to establish functional specifications to replace conventional method specifications. Existing performance and quality data for a product classification is gathered from the private sector to assist in the functional specification development.

For certification, a vendor presents its existing product data to the BBA. A formal evaluation process is initiated that, if successful, results in a BBA certification that the product meets the quality and performance intent of the specification. In British terms, the product is deemed “fit for purpose.” Trade secrets, such as constituents and manufacturing details, are not released, but instead are sealed by the BBA to be used during subsequent quality audits. The HAPAS process appears to be successful, eliminating the need for routine on-site testing and continual surveillance for these material categories. It also provides the vendor with confidentiality. Certifications are available to the agency or owner on the Internet.

|

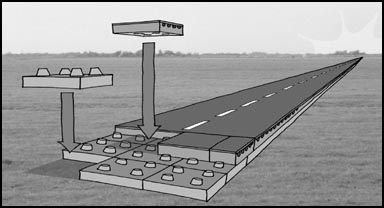

Figure 15. Very Silent Sounds Module from the Netherlands' Roads to the Future competition. |

|

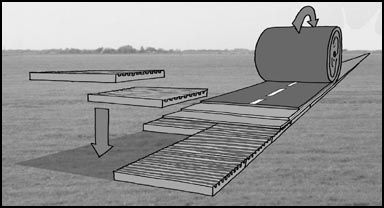

Figure 16. Roads to the Future rollable road. |

|

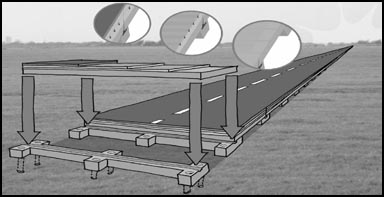

Figure 17. Roads to the Future ModieSlab pavement. |

|

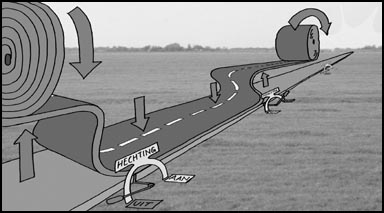

Figure 18. Roads to the Future adhesive road. |

|

Figure 19. Roads to the Future adhesive road. |

Other testing and evaluation organizations include the Building Research Establishment (BRE) and Transport Research Laboratory (TRL) of the United Kingdom, Danish Road Institute (DRI), Bundesanstalt für Straßenwesen (BASt) of Germany, and Dienst Weg-en Waterbouwkunde (DWW) and the Information and Technology Centre for Transport and Infrastructure (CROW) of the Netherlands. These organizations are prominent, well respected, and trusted within the highway community. Many times, a vendor desiring consideration of a material by an agency or contractor (e.g., on a warranty job) will seek the approval of one of these organizations.

Overall, the scanning team observed a number of common steps in most of the evaluation and certification processes it identified during the scan:

The process commonly begins with the vendor collecting and documenting data on material properties, behavior, and performance. The vendor has no incentive to take shortcuts on this step. Since the remaining steps require additional investment, the vendor wants to prove to itself that the material will not fail.

The vendor then approaches the evaluating organization, presenting the existing data and entering into a contract.

If the material falls into a new category, it may require a preliminary assessment of functional requirements for that category, including what properties should be tested to ensure the stated performance. This sometimes involves formation of a committee of experts in the field.

The material is then tested according to the specifications. If it passes, it is certified.

At this point, the vendor can approach the EOTA to gain additional certification of the material for more widespread use. The EOTA may accept the material based on the existing certification, or it may impose additional functional requirements, requiring further testing before certification.

|

Figure 20. Use of the torque bond test in the United Kingdom. (Photo Source: TPL Limited, UK) |

The Netherlands is using a novel approach to exploring long-range solutions to meet future highway demands. A Roads to the Future contest was held in which the highway agency defined a number of highway functional requirements (e.g., noise reduction and paving windows). Contractors were invited to offer solutions,

|

Figure 21. Accelerated pavement striping wheel test in Germany (Photo Source: BASt, German) |

no matter how unconventional. The agency was surprised by the tremendous response. It selected four techniques for further evaluation on a predefined test section, including options with precast polymer surfaces that were laid down from rolls (like carpeting). This somewhat radical experiment resulted in a paradigm shift from the traditionally conservative thinking of the Dutch highway industry. Funding for this effort was divided equally between the agency and the contractors,

|

Figure 22. Surveying with the ARAN test vehicle in the Netherlands. (Photo Source: DWW, The Netherlands) |

resulting in both shared risk and reward. A notable aspect of this experiment was the timeframe. The idea went from concept to final placement in two years.

|

Figure 23. Hot-mix asphalt microscopy in Denmark. |

In addition to exploring evaluation and approval processes, the team observed a number of innovative evaluation techniques. The following sections describe some of these techniques.

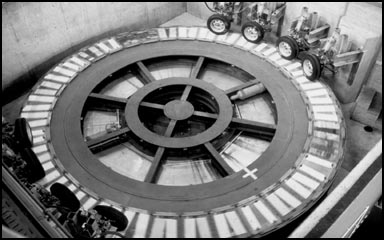

Through the use of both accelerated load testing and various forms of field testing, superior materials were evaluated for not just their properties, but also their performance. The national testing laboratories with the requisite equipment and facilities, especially for accelerated testing, commonly used these procedures. Vendors that wished to evaluate the performance of a product before seeking certification or specification sometimes initiated the demand for performance testing (note Item 2 under the section “Independent Product Evaluation and/or Certification” above). By testing under accelerated loading, long-term performance could be assessed in a limited timeframe. In addition, because the conditions were carefully controlled, this eliminated much of the inherent uncertainty of a field trial on an active highway.

|

Figure 24. Pulse (active) thermography in the United Kingdom. |

The countries the scanning team visited used a number of unique test methods to evaluate materials. While many have been used to some degree in the United States, the team believes that a renewed evaluation should be considered. A description of some of these methods follows.

Identified by the Highways Agency in the United Kingdom, this test is used to evaluate the in-place bond effectiveness of thin wearing course systems. According to the agency, the first step is to take a core through the pavement. A stud is then attached to the core surface and force applied with a torque wrench. The force required for failure is noted, as well as the location of the failure. For a well-bonded material, the failure occurs in the underlying material, and not at the bonded interface.

Because of the expense and logistics associated with field testing of lane markings (stripes), Germany has developed a laboratory facility for accelerated lane marking evaluation. This facility is capable of evaluating tape, temporary paint, and permanent paint markings. Since the facility began testing in 1989, nearly 2,000 materials have been tested. This specification can be found in CEN 13197.

|

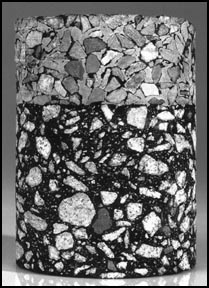

Figure 25. Twin-layer asphalt in Germany. (Photo Source: BASt, Germany) |

In the Netherlands, raveling of hot-mix asphalt wearing courses was identified as a critical distress type. During a demonstration of the national pavement management system, it was revealed that an automated technique has been developed that can assess the degree of raveling from the laser data collected by the automatic road analyzer (ARAN) test vehicle.

Figure 26. Helmholtz resonators on Roads to the Future test section in the Netherlands.

Figure 26. Helmholtz resonators on Roads to the Future test section in the Netherlands.

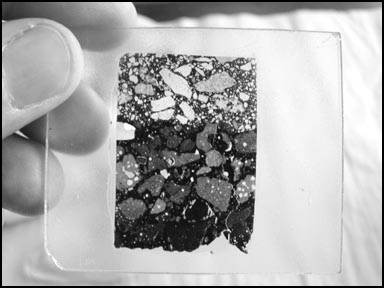

The Danish Road Institute demonstrated a technique for evaluating hot-mix asphalt samples that originally was developed as part of the SHRP research program in the United States, but has been improved on since then. The purpose of the test is to better identify a variety of behaviors, including stripping and microstructural damage. It includes two methods of preparing samples: one that results in a sample with a polished surface, and another termed “thin microscopy” that results in translucent wafers. These preparation techniques are commonly combined with dye impregnation to assist in imaging and interpretation.

It was observed that infrared testing for the presence of polymer within a binder sample was being used in the Netherlands. It was reported that an effort is underway to further this process by quantifying the polymer content using the same basic techniques.

The Building Research Establishment in the United Kingdom demonstrated an evaluation technique being deployed in the field to determine the bond effectiveness of composite laminate repairs for structures. While all thermography techniques record the thermal signature of a surface, this technique also employs an active heat source that, when pulsed, allows the evaluator to monitor the differential heat signature. The result is the ability to view delaminated areas beneath a composite laminate reliably.

|

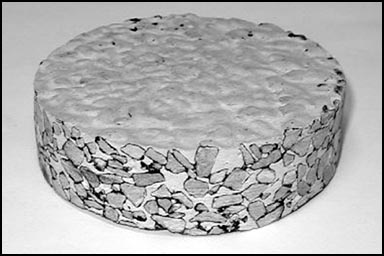

Figure 27. Semi-flexible pavement section in Denmark. (Photo Source: LOTCON ApS, Denmark) |

|

Figure 28. Stabiflex pavement section in Denmark. (Photo Source: Colas Danmark A/ S, Denmark) |

The scanning team learned about a variety of materials that meet the hosts' definition of superior materials. Like the test methods, a number of these materials have been introduced already in the United States, but are reported here to highlight their more widespread use (in some cases) in Europe. The team believes that some of these materials show promise for use in the United States as the pressures to better meet the needs and desires of the traveling public begin to dominate the decisionmaking process.

Porous asphalt pavements—Originally introduced to help with splash and spray issues, this pavement type has noise-attenuating properties that have made it popular in all of the countries visited. Some frictional issues that have been reported are believed to be due to the additives required to improve handling during the construction process.

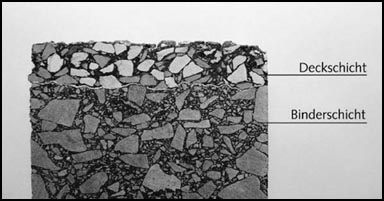

Twin-layer asphalt—While porous asphalts have become increasingly popular, difficulties have been reported with using them on lower-speed facilities. At high speeds, the traffic draws sand and other deleterious materials out of the pores, resulting in a self-cleaning surface. This does not occur, however, at the lower speeds typical of many city streets. A twin-layer paving system has been advanced that includes a larger stone porous matrix in a lower lift, covered by a porous mix with a smaller top size for the wearing course. The National Asphalt Pavement Association recently published an article on the use of twin-layer asphalts.

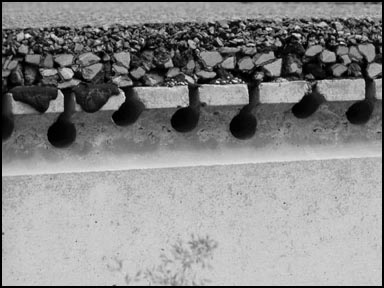

Helmholtz resonators—Since about 1990, European researchers have been evaluating techniques to reduce noise caused by tire-pavement interaction using carefully engineered voids cast into the pavement termed Helmholtz resonators. These voids serve to dampen sound induced by excessive air pressure created as a tire rolls over the pavement. The scanning team observed these resonators firsthand on the Roads to the Future project. In this case, they were precast into a concrete layer used on some test sections.

|

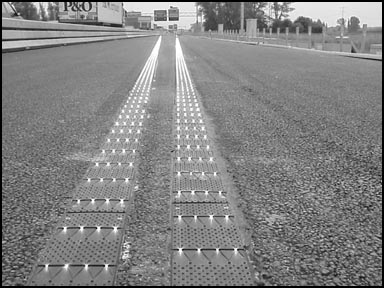

Figure 29. Dynamic road markings in the Netherlands. (Photo Source: Heijmans, The Netherlands. |

In the United Kingdom, the team observed a number of superior materials introduced to meet high-friction requirements. These materials must not only meet frictional requirements, but also tests for adhesion, freeze-thaw degradation, and wear.

|

Figure 30. Two-course paving in Germany. (Photo Source: BASt, Germany) |

Because of the large deflections that commonly occur, orthotropic bridge decks are difficult to surface. The steel deck must be protected by a waterproofing system, but balancing minimal permeability with the need for a long-life wearing course flexible enough to tolerate high deflections is a challenge. A multilayered system of various polymer-modified materials has been advanced to meet this challenge.

Using a variety of organic and/or mineral admixtures, the Germans developed a process to manufacture and pave hot-mix asphalt at lower temperatures. Drivers for this technique included demands for lower emissions and reduced energy requirements.

The team observed a variety of semi-flexible pavement systems that combine an open-graded hot mix skeleton with a polymer-modified grout. While some States in the United States have experimented with this type of pavement, some technology improvements observed in Europe may warrant further evaluation.

While the Europeans construct few new concrete pavements, exceptions exist. On some projects, especially those being constructed under DBFO contracts, composite pavements are used. This pavement type consists of a new continuously reinforced concrete pavement (CRCP) overlaid with a durable hot-mix wearing course. Because the wearing course can be removed and replaced with relative ease, the functionality (smoothness, friction, and noise) of the facility can be maintained more easily.

Termed “NEWPAVE” by the United Kingdom's TRL, this surfacing type is typically constructed as a 2-inch-thick concrete inlay for existing hot-mix asphalt pavements. Reinforced with both fibers and conventional mesh, the layer is rolled after placement to develop distributed microcracking rather than large working cracks.

In Germany, the scanning team observed a process for rapid panel repair of existing concrete pavements. Using a 16-cubic-meter mixer situated on a flatbed truck, the work is usually conducted at night. First, saw cuts are made on the cracked panel and the pieces are removed with a crane. Tie bars and dowel bars are then drilled and inserted, the concrete is placed, and a small vibrating screed is used for finishing. The roadway can be opened to traffic in 5 to 6 hours, since the process produces 4-hour strengths of 20 megapascals (Mpa) and 1-day strengths of 50 MPa.

|

Figure 31. External enclosure of bridges in the United Kingdom. (Photo Source: Highways Agency, UK) |

An innovative approach to increasing traffic capacity was introduced to the team in the Netherlands. Working with industry, the Rijkswaterstaat sponsored the development of embedded pavement lights that can be used in lieu of paving stripe. Positioned at strategic locations, the lights can be illuminated in two different patterns to add a lane during peak hours.

Additional observations include the following:

A unique hot-mix process was demonstrated in Germany that includes the laydown of two different lifts in a near-simultaneous fashion. The process made use of two pavers designed to work in tandem, with separate feeds for each paver. The result is the ability to place a thicker section, which could take advantage of a hot bond. Furthermore, because of the increased mass, the paving season could be extended into colder weather than in the past.

In all of the countries visited, the noise generated from vehicle-pavement interaction was found to have a profound effect on the decisions being made about pavement type selection. With many agencies requiring noise-reducing surfaces, industries were forced to respond quickly with viable and cost-effective solutions or face virtual elimination from the market. When the issue was first raised, the automotive, tire, and highways industries began to work together to identify common solutions.

As part of the accelerated load testing being performed in Germany, an assessment of pavement damage from truck (axle) loads is being made. The government believes that, based on the results of this testing, it can impose more rational taxation for trucks.

In the Netherlands, video units are being used at select weigh-in-motion (WIM) stations to identify overloaded vehicles in real time. The team believes that the same configuration could be used in the United States to identify unusual WIM data traditionally discarded during the data reduction process.

While visiting BRE in the United Kingdom, the scanning team learned about the results of a forensic investigation of concrete bridge piers. Severe deterioration of some concrete piers that were in contact with the native soils was observed. This deterioration was progressive and resulted in a complete loss of strength of the concrete. Thaumasite is believed to occur from a reaction between some types of concrete and aggressive sulfates under saturated and cool (less than 60° F) conditions. By better understanding the symptoms of this unique distress, guidelines for geotechnical investigations in the United States could be updated to increase the probability of identifying it in the field.

In the United Kingdom, a technique was demonstrated that includes enclosing the bottom and sides of bridge structures with a permanent shell. The enclosure does not provide additional structural capacity, but instead facilitates bridge construction, inspection, maintenance, upgrading, and operation with minimum traffic disruption. It also provides corrosion protection, environmental protection, improved safety, and clear boundaries among responsible authorities.

| << Previous | Contents | Next >> |