U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Selection of components includes specifications for aggregate quality. Specifications for coarse aggregate include LA Abrasion, micro-Deval, and percentage of crushed faces. Methylene blue tests are specified for fine aggregate and fillers. A minimum fine aggregate angularity, based on a flow test, is specified for surface courses. A maximum rounded sand content of 10 percent is recommended for surface and binder courses. Rigden voids and ring and ball softening point tests (or change in softening point) are also specified for the filler. Binder grades are not specified in the French specifications. The LCPC Design Manual notes, "To better prevent against cracking risks under severe traffic and climatic loading conditions, it would be advised to select the softest grade compatible with rutting resistance-based requirements."(9) Penetration grades are recommended for the various mix types, based on traffic loading, but the designer may adjust to meet type testing requirements.

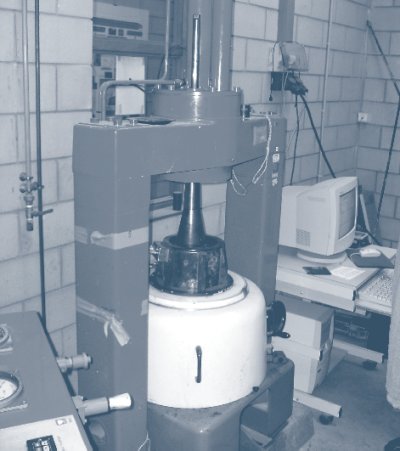

For a Level 1 design, a trial gradation is selected based on the mix designer's experience. A minimum richness modulus, essentially a film thickness, which in turn determines a minimum binder content, is specified for each mixture type. Samples are then prepared in the French gyratory compactor (figure 38) to assess the ability of the mix to be compacted in the field. The French specifications include a minimum void content at 10 gyrations and an acceptable void range at a specified number of gyrations (varies by mix type). It should be noted that the French gyratory compactor has a lower external and internal angle of gyration (1.00 and 0.82 degrees, respectively) than the Superpave gyratory compactor. The pressure used in the French gyratory is the same as that used in the Superpave gyratory compactor. Thus, the French gyratory provides less compaction than the Superpave gyratory for the same number of gyrations.

Level 2 designs add the large-scale wheel-tracking tester developed by LCPC to assess rutting potential. Samples are prepared at either 2 or 4 inches (5 or 10 centimeters) thick, depending on the intended lift thickness. The air void content varies by mix type and represents the anticipated in-place air voids. The samples are tested at 140 °F (60 °C) with a 1,124-lb (5-kN) vertical load, using a pneumatic tire inflated to 87 psi (6 bars). The load is applied at a frequency of 1 Hz.

The Level 3 design adds modulus and Level 4 adds fatigue testing. Modulus testing is conducted either on trapezoidal samples in two-point bending or on uniaxial tension-compression samples. Fatigue testing is conducted in two-point bending mode on trapezoidal samples at 50 °F (10 °C) and 25 Hz. Type test fatigue requirements are a minimum strain level that will provide a fatigue life of 1 million cycles.

Figure 38: MLPC Type II gyratory compactor.

| << Previous | Contents |