U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

About 75 percent of the population of Canada is concentrated within 100 mi (160 km) of the nation's southern border with the United States, with more than 60 percent living along the Great Lakes and St. Lawrence Seaway in the provinces of Ontario and Québec. Nearly 80 percent of Canadians live in urban areas. As in the United States and other highly developed nations, the economy is dominated by the service sector, which employs about 75 percent of all Canadians, about the same percentage as in the United States.(7) At the same time, the primary goods sector is an important part of the Canadian economy, especially the logging and oil industries. Possessing vast deposits of oil and natural gas as well as abundant hydroelectric power, Canada is one of the few developed countries that are net exporters of energy.

Canada has no federal equivalent of the U.S. Federal Highway Administration (FHWA) or American Association of State Highway and Transportation Officials (AASHTO). The provincial governments function largely independently. No federal funding goes to highways; the provinces are responsible for financing all highway work. Capital construction funds come from general revenue, not fuel taxes.

Ontario is the most populous of Canada's provinces, home to nearly 13 million people, about 38 percent of the total population of Canada. Most of Ontario's population and economic activity are concentrated in the southeastern portion along the Great Lakes and the St. Lawrence Seaway.

The key high-volume highways in Ontario are the 400-series highways in the southern part of the province. The most important of these is the 401, the busiest highway in North America, with average annual daily traffic (AADT) of more than 425,000 vehicles in 2004, and daily traffic sometimes exceeding 500,000 vehicles. In much of the Toronto area, the 401 has six lanes in each direction, but some segments have seven, eight, and even nine lanes in each direction. The next most heavily trafficked freeways in the 400 system are the 427, with an AADT of about 312,000 vehicles, and the Queen Elizabeth Way, with an AADT of about 175,000 vehicles.

Ontario is a cement-rich province, and as a result, Canada is able to satisfy all of its domestic cement demand and export its surplus. In 2004, Canada exported about 7 million tons (6.4 million metric tons) of cement, of which about 6.3 million tons (5.7 million metric tons) went to the United States.(8) The United States, in contrast, despite being the world's third-largest producer of cement, can meet only about 75 percent of its domestic cement demand and must import the other 25 percent.

In the 1980s, the Ontario Ministry of Transportation (MTO) began using life-cycle cost analysis in its pavement type selection process. Pavement design alternatives are compared based on present worth over a 50-year analysis period. Concrete pavements are assumed to have an initial service life of 28 years to the first rehabilitation; asphalt pavements are assumed to have an initial service life of 19 years.

MTO uses a social discount rate, set by the Ministry of Finance, in life-cycle cost analysis. A social discount rate, also called a social or societal rate of time preference, "reflects the government's judgment about the relative value which the community as a whole assigns, or which the government feels it ought to assign, to present versus future consumption."(9) The societal time preference rate "need bear no relation to the rates of return in the private sector, interest rates, or any other measurable market phenomena."(10)

In MTO's life-cycle cost procedure, the salvage value of a pavement is defined as the prorated remaining life at the end of the analysis period. User costs are not currently incorporated in the life-cycle cost procedure; MTO is studying what user cost model would be most appropriate.

MTO implemented alternate bid contracts on major freeway projects in 2001. Alternate bid contracts allow both the asphalt and concrete industries to bid on the same contract. Since then, concrete has been selected for all six of the alternate bid contracts awarded. MTO sets bid adjustment factors in advance based on life-cycle cost analysis results. Alternate bid contracting procedures result in higher upfront engineering costs for MTO because two separate sets of bid documents must be prepared. However, allowing the two industries to compete on the work has resulted in US$23 million (Can$26 million) in savings in initial construction costs. (Note: all currency conversions to U.S. dollars in this report are based on late April 2007 exchange rates.)

Ontario's most prominent experience with public-private partnerships to date is the 407 (shown in figure 3), originally planned as a bypass for the 401 and leased to a private consortium in 1999 for about US$2.8 billion (Can$3.1 billion). This purchase price covered the existing 43-mi (69-km) central section (built as concrete pavement) and the right to build extensions on the east and west ends (these extensions were built as asphalt pavement) to increase the full length of the highway to 67 mi (108 km). Work is already underway to widen 30 mi (50 km) in the central section from six to eight lanes, and another 30 mi (50 km) of widening is planned. By the end of 2020, nearly the entire 67-mi (108-km) length will have 10 lanes, with one short section having eight lanes.

Figure 3: Highway 401 at 407 ETR.

The 99-year lease agreement allows for the private operation of the 407 ETR (electronic toll road), but requires adherence to the provincial government's highway safety and design standards and auditing on a regular basis. MTO conducts about 10 audits of the 407 ETR and its subcontractors and subconsultants per year. In addition, an independent auditor, hired by and reporting to both parties, conducts frequent auditing.

The 407 ETR is the world's first all-electronic, open-access tollway. Electronic sensors mounted on overhead gantries at on- and off-ramps detect transponders mounted on vehicle windshields and log toll transactions (see figure 4). Trips on the 407 by vehicles not equipped with transponders are logged using a state-of-the-art license plate recognition system (by law, transponders are mandatory for vehicles with gross weights of 5 metric tons or more). Users receive monthly statements by mail and can check their account balance and sign up for automatic credit card billing on the 407 ETR Web site.

Figure 4: Vehicle passes under electronic sensors on gantry at on-ramp to 407 ETR.

Traffic on the 407 ETR averages about 300,000 trips per day. Tolls on the 407 ETR are about five times higher than on the New York State Thruway. A trip from one end of the 407 ETR to the other costs about US$18 (Can$20). The leaseholder sets tolls for trucks much higher than for cars, with the intent of shifting truck traffic to the public highway system.

Ontario anticipates that major new roadway construction will be done by public-private partnerships (PPP). The ministry is exploring PPP contracts or area-term contracts, in which a private contractor will be responsible for design, rehabilitation, and maintenance of all provincial roads within a certain geographic area. PPP contracts are viewed as a growing trend throughout Canada, consistent with a trend of government downsizing out of operations and into a management role.

In the province of Québec, concrete pavements make up 767 two-lane mi (1,239 two-lane km) of the 18,000-mi (29,000-km) road network, only about 4 percent, but carry about 75 percent of Québec's traffic. Most of this concrete pavement is in and around the city of Montréal. Québec builds both jointed plain concrete pavements and continuously reinforced concrete pavements. The appeal of the CRCP option is the "get in, get out, stay out!" aspect that is important because of the limited funds available for pavement maintenance. Life-cycle cost calculations conducted by the Québec Ministry of Transport (MTQ) indicate that for one case, CRCP is about 5 percent lower in cost than JPCP in terms of net present value over a 50-year analysis period. The actual life-cycle cost differential for a specific route depends on the traffic level.

MTQ has used life-cycle cost analysis since the mid 1990s. Projects over about US$900,000 (Can$1 million) are subjected to life-cycle cost analysis to help in the selection of the best construction or rehabilitation alternative. A 50-year analysis period is used, and discount rates between 4 and 6 percent are considered. Both residual value and work zone user costs are considered in the life-cycle cost analysis. MTQ uses two computer programs to conduct life-cycle cost analysis: one (RealCost) developed by the U.S. FHWA and one (Visual LCCA) developed by the Transportation Research and Development Institute (TRDI).

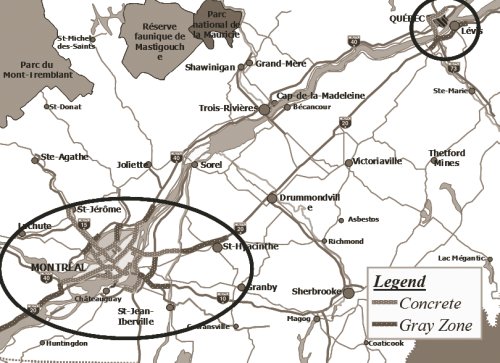

In 2001, Québec adopted a departmental policy on pavement type selection that dictates which routes in the Montréal and Québec city areas—a total of 484 mi (779 km)—will be concrete pavement. The choice of JPCP or CRCP for pavements in the "white zone" is a regional decision, which can be based on life-cycle cost analysis but does not necessarily need to be. Another 226 mi (364 km) of nearby routes are classified by the policy as being in the "gray zone," and for these routes, life-cycle cost analysis and other factors (environmental concerns, technical criteria, and economic consequences) are to be used in pavement type selection. The policy dictates that all other routes in the province will be asphalt pavement. Figure 5 illustrates the assignment of routes to the concrete and gray zone groups. This assignment of concrete pavement to specific routes largely corresponded to the location of existing concrete pavements in the province, and was well received by government authorities and industry.

Figure 5: Concrete and "gray zone" routes for which a multiple-criteria analysis is used in pavement selection type, according to the Québec Ministry of Transport.

MTQ uses pavement management software called Visual/PMS, developed by TRDI, to store pavement construction, inventory, and condition data; project future pavement conditions; and assist in developing long-term maintenance plans.

Québec embraced the concept of public-private partnerships as part of its 2004–2007 Modernization Plan. MTQ considers three types of PPP contracts as options for large projects: (1) design and construction, (2) delegation of exploitation and maintenance, and (3) conception-design-maintenance-exploitation and funding. Planned PPP projects are the completion of Highways 25 and 30 around Montréal, and construction and maintenance of several rest areas.

The Highway 30 project, which will have a cost of about US$900 million (Can$1 billion), involves a 22-mi (35-km) stretch of highway and 4 mi (7 km) of other roads to complete a link between Châteaugauy and Highway 20 in Ontario. Plans are for this work to be done under a conception-design-maintenance-exploitation and funding arrangement, but whether this will be a concrete pavement has not been determined.

Germany considers concrete pavements to be long-life pavements, and jointed plain concrete pavements make up some 25 percent of the German high-volume motorway network. Germany has no long-term experience with continuously reinforced concrete pavement on motorways. The scan team visited a 0.9-mi (1.5-km) stretch of CRCP test sections built in 2005 on the A-5 Autobahn near Darmstadt.

When a new motorway or reconstruction is planned, the government issues a request for proposals, specifying the construction class (e.g., motorway). Bidders use the catalog to select the type of construction (asphalt or concrete pavement and base type). Alternative offers with different construction types are permitted.

The bidders' offers include only the initial construction cost, not life-cycle costs, and while the concrete pavement alternatives tend to have a slightly higher initial cost than the corresponding asphalt pavement alternatives, concrete pavements are given a credit of US$0.22 per square foot (€1.80 per square meter) because their maintenance costs are presumed to be lower. The selection of this value was arbitrary and the German cement industry believes it is too low, although it has not yet proposed another specific value.

On government-funded projects (as opposed to public-private partnerships), contractors must provide a 4-year warranty for concrete and asphalt paving. Regulations are being developed to stipulate the functional requirements of the pavement at the end of the 4-year warranty period. In addition to the mix design, the contractor is responsible for construction testing of concrete strength, air content, thickness, smoothness, and skid resistance.

For PPP projects, the construction company is responsible for constructing the road and maintaining it for up to 30 years. Some PPP projects have maintenance periods of 20 or fewer years. The contractual provision related to maintenance becomes void at an earlier age if the actual accumulated traffic loadings reach the traffic loadings forecasted for the contract-specified maintenance period. The construction company derives its revenue from tolls. Life-cycle costs play a role in the construction method selected because alternatives with lower life-cycle costs yield higher profits for the construction company. Public-private partnerships are less common than conventional construction contracting arrangements.

Three types of alternative contracting models have been employed in Germany for public-private partnership contracts for road construction projects of 6 to 9 mi (10 to 15 km). Under the "functional building contract" (or "C") model, a 30-year contract is let to build and maintain the road, with financing from the Federal budget. Four pilot projects, two in asphalt and two in concrete, totaling about 25 mi (40 km), have been built under this model. Under the "F" model, a maximum of 20 percent of the startup financing comes from the Federal budget; the remainder of the construction and maintenance costs is paid by tolls. Several concrete and asphalt pavement projects have been built using this model. The "A" model is similar to the "F" model except that 50 percent of the startup financing, rather than 20 percent, comes from the Federal budget. About 148 mi (238 km) of roadways have been built under five contracts using "A" model financing.

A pavement management system maintained by the Federal Highway Research Institute (Bundesanstalt für Straßenwesen, BASt) is used to store construction information, monitoring data (friction and high-speed profile measurements), traffic data, and accident data. Noise data are not collected.

Most monitoring data are collected by contractors, with government oversight in each German state. Monitoring data are collected on a 4-year cycle; during the first 2 years the expressways are measured and during the second 2 years the other federal trunk roads are measured. The pavement management system is used primarily to generate short-term maintenance plans.

Motorways make up about one fourth of Austria's Federal road network (8,700 mi (14,000 km)).(11) About two thirds of high-volume motorways (about 2,485 one-directional mi (4,000 one-directional km)) are concrete pavements.

Austria built its first concrete pavement in 1925 and its first motorway just before World War II. Austria's high-volume roadways constructed after World War II were built in concrete, following the model of the German Autobahns. At the time, bituminous pavement designs for heavy traffic had not been developed, and there was no competition for concrete for high-traffic applications. In the 1970s, the Ministry of Transport adopted a pavement plan dictating which pavement type would be used for which roadways, as a function of truck traffic volume, soils and geologic conditions, and local government preferences.

The ministry's pavement type selection plan was abandoned in the 1980s, and the life-cycle costs began to be considered in pavement type selection. Asphalt pavement technology developed rapidly in Austria in the 1980s. Concrete pavements were also viewed during this era to be too expensive, noisy, and difficult to repair. Budget constraints in the 1980s required financing of motorway construction by loans, and cost-cutting measures such as reductions in layer thicknesses and lane and shoulder widths were instituted.

Something of a renaissance in concrete pavement technology in Austria began in the early 1990s, when a program of reconstruction, widening, and geometric improvements of some of the older roads in the network began in 1990. Figure 6, for example, shows a section of the A1 motorway between Vienna and Salzburg, originally constructed in concrete between 1959 and 1961 and reconstructed in concrete in 2003. Among the technological improvements that contributed to increased use of concrete pavements in Austria beginning in the 1990s were the development of techniques for exposed aggregate surfacing, recycling of old concrete pavements, and rapid repair methods. Increasing traffic volumes and a decrease in the price difference between asphalt and concrete pavement also contributed to resurgence in concrete pavement construction. With the collapse of the Soviet Union and the opening of previously closed borders to the east, truck volumes on Austrian roads have increased and are expected to continue increasing greatly.

Figure 6: The A1 motorway in Austria, reconstructed in 2003 after more than 50 years of service.

Not all of Austria's concrete pavements built in the 1950s and 1960s have been reconstructed. One such road is the Mölltalroad, in the Carinthia region in southern Austria, which opened to traffic in 1956. About half of its original length (some 30 mi (50 km)) is still in use and in good condition. The remaining half was redesigned to improve the alignment and intersections. The road is located in a mountainous area. Along its length, its average annual daily traffic ranges from 3,325 vehicles (5.7 percent trucks) to 6,136 vehicles (4.5 percent trucks). The Mölltalroad's concrete surface is only 8 inches (in) (20 centimeters (cm)) thick, and was constructed on grade without any base layer. Despite the inadequacy of its design by modern Austrian standards, it still has good smoothness and friction and little distress after 50 years in service.(12)

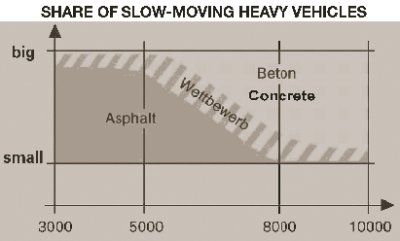

In the late 1990s, the Austrian Association for Research on Road, Rail, and Transport (FSV) developed the guide document RVS 2.21, Economic Evaluation of Different Pavement Alternatives, which became mandatory for use in pavement type selection for all Federal roads in 2001. Today, pavement type selection is done using life-cycle cost analysis as outlined in RVS 2.21. In general, concrete is preferred for heavy-duty roads (over 8,000 heavy vehicles per day) and for roadway sections with slow-moving, heavy traffic. Figure 7 illustrates conceptually the roles that average annual daily heavy truck traffic and proportion of slow-moving heavy vehicles in the traffic stream tend to play in the choice between asphalt and concrete.

Figure 7: Influence of traffic volume and proportion of slow-moving heavy vehicles on pavement type selection in Austria.

In Austria, concrete pavements are viewed as the economical pavement choice for heavily loaded roads in the following cases:

Proper design (thickness, joint spacing, dowels, etc.) and uniformly high construction quality along the length of the project are believed to be crucial to attaining the life-cycle benefits of concrete pavements.

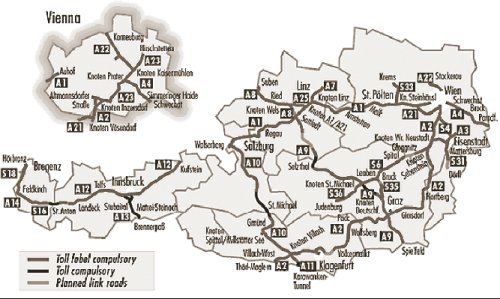

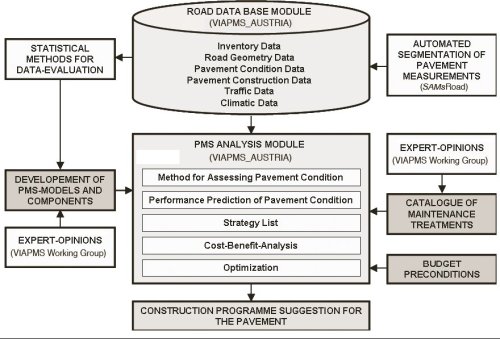

Austria has a sophisticated pavement management system used to store pavement data, forecast pavement conditions, and conduct life-cycle cost analysis of pavement maintenance strategies. Austria uses pavement management software called VIAPMS (a commercial pavement management program developed by a Canadian company) to manage its road network. A key component of this network is the motorway network, shown in figure 8. The structure of the Austrian pavement management system is shown in figure 9.

Figure 8: Austrian motorway network.

Figure 9: Structure of Austrian pavement management system.

Network-wide pavement condition monitoring includes collection of data on rutting, friction, roughness, cracking in concrete pavements, and surface defects. To keep the number of pavement sections in the database manageable, a dynamic segmentation algorithm is used to combine similar sections based on condition as well as inventory data.

Friction, rutting, and longitudinal profile data are used to compute a Comfort and Safety Index (CSI) for each pavement section, while surface defects, slab cracking, and (for concrete pavements) age are used to compute a Structure Index (SI). These indexes are used to compute a Total Condition Index (TCI) for each pavement section, which is the parameter used in network-level optimization algorithms.

Linear and logarithmic regression models are used to project future pavement conditions. Simplified models and a limited number of regression variables (age, equivalent single-axle loads (ESALs), a design index, and a frost index) are used for various pavement types. A recent research project in conjunction with the Technical University of Vienna focuses on improving the existing pavement condition prediction models and developing new ones.

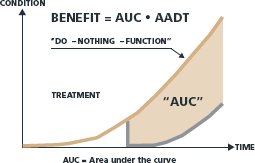

The cost-benefit analysis routine of Austria's VIPMS system uses incremental benefit-cost analysis to select from among multiple treatment options for each of the many pavement sections in the network. Benefit is quantified as the area between the forecasted condition curves of the treatment option and the do-nothing alternative, weighted for traffic. Figure 10 illustrates this benefit definition.

Figure 10: Calculation of benefit for each pavement treatment strategy considered in the incremental benefit-cost algorithm in Austria's pavement management system.

Work is underway to develop a user cost model for the Austrian pavement management system that takes into account travel time, fuel consumption, and accidents. The model is expected to be ready to implement in 2007.

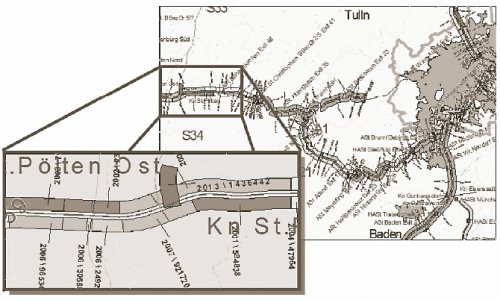

Among the outputs of the VIAPMS software are color-coded maps illustrating road condition by pavement section, as shown in figure 11. The portion of roadway highlighted in figure 11 is on the A1 motorway between Vienna and St. Pölten.

Figure 11: Pavement section condition mapping by Austrian pavement management software.

Pavement surface friction is a significant safety consideration in Austria, especially in mountainous areas with heavy snowfall, steep gradients, and numerous tunnels. Friction testing is mandated in Austria for construction acceptance and at the end of the warranty period. Periodic friction testing of in-service pavements is also conducted for network-level pavement management purposes. Three cycles of friction testing of the entire motorway network have been conducted (1991–1994, 1994, and 2004–2005), as well as two cycles of friction testing of the trunk roads network (1991–1996 and 2001–2002).

Friction testing in Austria is done with a vehicle called a RoadSTAR (Road Surface Tester of Arsenal Research), developed by Austrian arsenal research experts in cooperation with the Stuttgart Research Institute of Automotive Engineering and Vehicle Engines. RoadSTAR's measuring equipment is mounted on a two-axle truck with a 1,585-gallon (6,000-liter) water tank. RoadSTAR is capable of measuring surface friction at driving speeds of 25 to 75 miles per hour (mi/h) (40 to 120 kilometers per hour (km/h)), and at a speed of 50 mi/h (80 km/h) can measure friction on pavements with gradients of up to 8 percent. Recently, examination of friction acceptance testing data has revealed that new pavements in tunnels tend to have noticeably lower friction levels than other new pavements on the road network, and a national research study has been launched to investigate the reasons for this difference.(13)

Today, management of the Austrian motorway network is the responsibility of a rather unusual form of public-private partnership: a private company owned by the Austrian Federal government. The Austrian motorway company ASFiNAG (Autobahnen und Schnellstrassen Finanzierungs Aktiengesellschaft) plans, finances, maintains, and operates the entire Austrian motorway and expressway network. ASFiNAG was formed as a financing company in 1982 as a step toward achieving a balanced national budget, a requirement for entry into the European Union. In 1997, its scope of responsibilities was increased through the Austrian government's passage of the ASFiNAG Authorization Act. ASFiNAG is authorized to charge tolls and receive any income generated from property or other installations on the Federal road network. It is not authorized to set the tolls; that authority remains with the Austrian government. ASFiNAG is a public limited company and its shares are held entirely by the Republic of Austria.

At the beginning of 2004, a fully electronic distance-related toll system for vehicles with a total weight over 3.5 tons (3.1 metric tons) was introduced on the primary road network. From this design-build-finance-operate public-private partnership (DBFO PPP) with EUROPASS, a subsidiary of the Italian firm AUTOSTRADE, ASFiNAG expects revenues of about US$816 million (€600 million) per year and another US$816 million (€600 million) per year from tolls charged on lighter vehicles.

ASFiNAG has planned four packages of motorway improvement contracts to be let as public-private partnerships. These packages make up a program for building 70 mi (113 km) of roads in eastern Austria around Vienna to reduce traffic congestion in the Vienna area, improve traffic movement between Vienna and areas to the north, and provide an efficient north-south connection with the Czech Republic.(14)

Linguistically and culturally, Belgium is composed of two regions: the Dutch-speaking Flanders region to the north, where Brussels, the capital of Belgium, is located and the predominantly French-speaking Walloon region to the south. Legally, Belgium is composed of three regions: the two aforementioned and the capital region of Brussels, where both French and Dutch are spoken. Three separate road administration authorities oversee matters relating to road construction and maintenance in these three regions. Belgium does not have dedicated funds for highways; general revenue funds are used.

Belgium is densely populated—10 million people in an area of 11,600 square miles (30,000 square kilometers), less than the size of Maryland. About 10 percent of the population resides in Brussels, another 60 percent lives in Flanders, and the remaining 30 percent lives in Wallonia. The economy of Belgium is highly service oriented, and the Flanders region has one of the highest per capita GNPs in the European Union. The Walloon economy lags about one quarter behind in terms of personal income.

A large portion of the Belgian motorway network has been constructed in continuously reinforced concrete pavement. Belgium and France are the only two European countries to have employed CRCP on a large scale; Belgium in particular has embraced it enthusiastically. Even more interesting for the purposes of this scan is the fact that Belgium's CRCP design and construction technology was adapted from the United States. With the Belgian motorway network largely complete, much of the current investment in roads is allocated to renovation of the oldest concrete pavements in the network. Some old asphalt roads are also being replaced with concrete, sometimes by complete reconstruction and sometimes by a concrete inlay of the outer traffic lane.

Environmental awareness is a significant public and political influence in Belgium. Tire-pavement noise and recycling of construction materials are factors in pavement design, materials, and construction choices made in Belgium. As one recent Belgian research paper(15) puts it:

"While most people are now convinced that concrete can be a preferred solution in economical terms, when taking into account the whole-life cost including maintenance and if possible costs to the user, it has certainly become just as important to show that concrete roads are environmentally friendly and sustainable."

The Belgian concrete industry produces about 30 million tons (27.2 million metric tons) of concrete and concrete products every year. Concrete has a good reputation in Belgium for being recyclable at the end of its life. In addition, in the Flanders region, about 85 percent of all rock-like building rubble is recycled. Two-lift construction, wherein lower quality materials are used in the thicker lower lift and higher quality, more wear-resistant, more durable aggregates are used in the thinner upper lift, has been used for a few special projects in Belgium. Good-quality aggregates are readily available in Belgium, so recycling of crushed concrete in the bottom layer has not been done in Belgium. A first trial of this type of construction, however, is planned. The exposed aggregate surface finishing technique popular in Austria is also used in Belgium. Both Belgium and Austria have found that one of the low-noise surface alternatives, a porous concrete surface, tends not to remain very porous or quiet for very long.

The Walloon and Flanders regions are responsible for nearly equal amounts of the Belgian motorway network (both between 530 and 560 mi (850 and 900 km)), and the Brussels region is responsible for a smaller amount (7 mi (11 km)). Overall, Belgium has the highest roadway density (length of roads per unit land area) of any country in Europe, followed closely by the Netherlands.

The Belgian road network consists of about 83,000 mi (134,000 km) of motorways and regional, provincial, local, and rural roads. Motorways make up about 1,100 mi (1,700 km), just over 1 percent, of this total. Concrete pavements make up 40 percent of these motorways. Concrete pavements are used more on lower-volume roads in Belgium than in most of the other countries visited on this scan, even rural roads, 60 percent of which are concrete. Overall, concrete pavements make up 17 percent of all roads in Belgium.

Belgium has many examples of concrete pavements that have provided several decades of service. Belgium's first concrete pavement, Lorraine Avenue, shown in figure 12, was constructed in 1925 and remained in service until 2003, when it received a concrete overlay.(16)

Figure 12: Belgium's first concrete pavement, built in 1925, remained in service for 78 years.

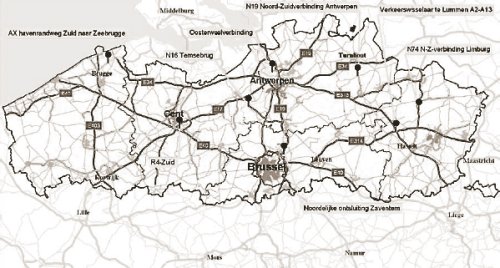

In the Flanders region, management of the roadway network (shown in figure 13) is the responsibility of the Infrastructure Agency (IAA) in the Flemish Ministry for Mobility and Public Works. With a staff of about 1,600, the agency manages a network of some 3,900 mi (6,300 km) of roads and 4,200 mi (6,700 km) of bicycle paths. Highways make up 531 mi (855 km) of the Flemish road network. The annual budget of IAA is about US$426 million (€313 million), of which US$303 million (€223 million) is earmarked for investments in the road network and US$121 million (€89 million) for road maintenance.

Figure 13: Major roads in the Flemish region of Belgium.

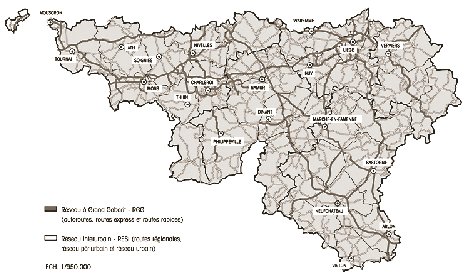

In the Walloon region, management of the roadway network (figure 14) is the responsibility of the Directorate-General of Highways and Roads in the Walloon Ministry of Equipment and Transport. With a staff of about 1,600, the Directorate-General manages a network of some 540 mi (870 km) of motorways and some 4,200 mi (6800 km) of other roads. The annual budget of the Directorate-General of Highways and Roads is about US$265 million (€195 million). About US$83 million (€61 million) of this goes to motorway and road investments, about US$91 million (€67 million) goes to routine maintenance (which includes winter maintenance), and about US$66 million (€49 million) goes to special maintenance projects.

Figure 14: Major roads in the Walloon region of Belgium.

Life-cycle cost analysis is not used for pavement type selection at the project level in Belgium, except for large projects. A recent report by the Walloon Ministry of Equipment and Transport (MET) demonstrates why CRCP is the predominant pavement type used on motorways. In an economic comparison of asphalt pavement and CRC pavement for motorways, asphalt pavement was found to have lower initial construction costs, but CRC was judged more cost-effective over any analysis period greater than about 14 years.(17)

Primarily for non-motorway roads, the MET is developing a multicriteria analysis method for pavement type selection. The quantitative factors considered include cost, rutting resistance, skid resistance, cracking rate, and noise. The qualitative factors considered include surface and subsurface drainability, disruption to traffic, inconvenience for the public, ease of access to utilities for future repairs, compatibility with other pavement types nearby on the route, suitability of the surfacing for local conditions, ease of maintenance, ease of construction, susceptibility to frost damage, and ease of winter maintenance.(18)

No roadway projects have been constructed in Belgium by a public-private partnership, though PPPs are being used for other types of public projects (e.g., school construction). However, six large roadway improvement projects now in the planning stages will be done as public-private partnerships. For these projects, the contractor will contribute to the initial construction cost and will be responsible for maintaining the roadway for 30 years. Functional requirements (friction and ride) will be defined for these projects and will not necessarily be the same functional requirements used for publicly managed roads. Lane rental fees will be charged every time during the 30-year period that the contractor closes a portion of the road for repairs.

The Netherlands, with a population of 16 million, is the most densely populated country in Europe. Despite its relatively small size and the fact that 18 percent of the country's area is water, food processing is an important industry in the Netherlands. It is the world's third-largest exporter of agricultural products, after the United States and France. The energy sector is another important part of the Dutch economy. The world's second-largest oil company, Royal Dutch Shell, is based in the Netherlands, and one of the world's largest natural gas fields is located in the northeast part of the country. Nonetheless, gasoline consumption is heavily taxed; gasoline prices are higher in the Netherlands than in any other country in Europe and two to three times higher than in the United States. Funding for highway projects comes from fuel taxes and vehicle registration fees. Of the 24 percent of the annual public works budget of nearly US$11 billion (€8,000 million) that goes to highways, about 60 percent goes to construction and about 40 percent to operations and maintenance.

The roadway network of the Netherlands consists of some 70,000 mi (113,000 km) of roads. Some 1,400 mi (2,300 km) are motorways, only 2 percent of the total by length, but these motorways carry 38 percent of all traffic by volume. Five percent of the motorway mileage in the Netherlands is concrete pavement. About half is CRCP and the other half is JPCP. The country also has 87 mi (140 km) of JPCP on the regional roadway network. Overall, concrete pavements make up about 4 percent of the roads in the Netherlands. In addition to roadways for motorized traffic, the Netherlands also has 12,000 mi (20,000 km) of bicycle paths, 10 percent of which are concrete.

The Noise Abatement Act of 1985 stirred discussion in the Netherlands about traffic noise associated with different types of pavement surfaces. Concrete pavements with the traditional brushed finish were found to produce about 3 dBA (decibels adjusted) more noise than that of the reference pavement surface (dense asphalt concrete) defined in the Prescribed Standards for the Calculation and Measurement of Traffic Noise. In the late 1980s, the Motorways Department decided to address this issue by using porous asphalt concrete surfacing on concrete pavements.

In general, concrete pavement is favored over asphalt pavement for Dutch roads with average annual daily traffic levels of about 50,000 vehicles per direction or more. Concrete is also preferred for roundabout construction. In the late 1980s and early 1990s, the prevailing practice to reduce surface noise with concrete pavements was to apply a porous asphalt surface course. In the mid 1990s, however, the Netherlands began to experiment with exposed aggregate finishes for concrete pavement, in either one-lift or two-lift construction.

In recent years, interest in concrete pavements has revived because of their lower life-cycle costs and maintenance needs— heavy traffic congestion being an obstacle to lane closures for pavements, especially around the four big cities of Amsterdam, Rotterdam, The Hague, and Utrecht. While concrete pavements have higher initial construction costs and are not considered in the Netherlands as environmentally friendly as asphalt pavements, the drawback of asphalt pavements is seen to be their higher maintenance costs, with intervention required more frequently to remove ruts and extend service life. This renewed interest in longer-life concrete pavements coincides with a trend toward government downsizing in the Netherlands, with public-private partnerships expected to play an increasingly important role in roadway investment and maintenance.

In the past 5 years, design-build contracts for road construction with a 7-year warranty period have become increasingly common in the Netherlands. Contractors' bids for design-build contracts will be rated according to the following weighting scheme:

In contracts awarded after 2007, the government will make the decision on pavement type, but the contractor will be allowed to select the design details, using the government's pavement design software.

A CROW working group of representatives of government, industry, consultants, and contractors has been formed to develop a decision support model to select pavement type and design details as a function of economic, environmental, and other factors.(19) Up to six design options can be compared in a single analysis. For each option, the user must enter or select data on the composition of the pavement, subbase, and sand bed for the road type in question. The program includes default pavement cross-sections for different pavement types and road classes.

The three major factors used in the Dutch decision support model are costs, environmental impact, and other factors. Costs include those for construction, reconstruction, maintenance, and demolition. All costs are calculated based on net present value. Environmental impact is assessed using a model that considers both quantitative (e.g., emissions) and qualitative (e.g., nuisance) components. The "other factors" category gives the user the latitude to consider a range of other items of potential interest.

In 1995, the Dutch government decided that the economic assessment of national projects must take into account a 4 percent discount rate. For this reason, the multicriteria decision support program uses a default discount rate of 4 percent. According to the developers of the Dutch decision support model, other European countries use different government-set discount rates (e.g., Germany uses 3 percent, the United Kingdom 6 percent, Denmark 7 percent, and France 8 percent), while the European Union considers 5 percent an appropriate discount rate.

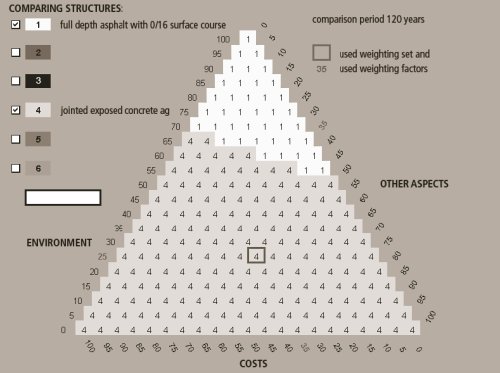

The decision support model uses a criteria weighting system, perhaps the most debated aspect of the model, because the subjective assignment of weights influences the outcome of the analysis. The counterargument is that not applying weights to the decision criteria would in fact be a form of weighting too, but one that would not allow the flexibility to consider priorities that might be different in the future than they are today.

For the three major decision criteria used in the program (costs, environmental impact, and other factors), a weighting triangle, shown in figure 15, can be used to compare different sets of weights and indicate the degree to which the weighting set influences the final result. The sides of the triangle represent the weighting factors for the "cost," "environmental impact," and "other factors" criteria on scales of 0 to 100 percent. The pavement alternatives evaluated in the analysis are numbered (up to a maximum of six; only two alternatives are compared in the example shown in figure 15). Each cell in the triangle represents a possible combination of the three factors' weights, and the number in each cell is the design alternative favored for that combination. The box around the cell represents the actual combination of factor weights used in the present analysis. The box's proximity to any boundary where the preferred option changes is a graphical illustration of the sensitivity of the result to the combination of weighting factors selected.

Figure 15: Triangle illustrating sensitivity of multicriteria analysis results to weighting factors.

While concrete pavements traditionally have not been as popular in the Netherlands as in some other European countries, they have long been popular in parts of the country, especially in the southern province of Noord-Brabant. Here, concrete pavements have been constructed steadily since the 1950s, and about 35 percent of the roadway network now consists of concrete pavements. In a recent survey of the pavement construction and maintenance practices in Noord-Brabant and other Dutch provinces, a key finding was that "the analysis data confirm the generally held, but not yet substantiated, notion that a concrete pavement is practically maintenance-free during its lifespan."(20)

The same study arrived at a summary, shown in table 1, of typical design lives and actual expected lifespans for four types of concrete pavements on Dutch roads of different functional classes. These actual lifespans are based on more than 50 years of experience in the Netherlands. Type 1 roads are on the primary roadway network and on motorways managed by the Motorways Department and the provinces. Type 2 roads are heavily used roads and county roads managed by the provinces. Type 3 roads are moderately used roads, access roads, and bus lanes managed by the provinces, municipalities, and water boards. Type 4 roads are lightly used roads and farm tracks managed by municipalities and water boards.

Table 1: Expected lifespans for different classes of Dutch concrete roads.

| Road Type | Design Life, years | Expected Lifespan, years | Comment |

|---|---|---|---|

| 1 | 30 | 45 to 50 | Provincial concrete roads |

| 1 | 30 | 30 to 40 | Concrete motorways |

| 1 | 30 | 25 to 30 | Motorways subject to overloading (not representative) |

| 2 | 30 | 40 to 50 | Provincial concrete roads |

| 3 | 30 | 40 to 50 | Water board roads |

| 4 | 20 to 30 | 40 to 50 | Municipal concrete roads |

| 4 | 20 to 30 | 25 to 30 | Water board farm tracks (not representative) |

The United Kingdom is a political union made up of four countries: England, Scotland, Wales, and Northern Ireland. The United Kingdom also has several overseas territories, including Gibraltar and the Falkland Islands. The United Kingdom is a constitutional monarchy with close relationships with—but not direct administrative control over—15 other Commonwealth countries that share the same monarch, Queen Elizabeth II, as head of state.

With more than 58 million people, the United Kingdom is the third most populous state in the European Union, after Germany and France. About 83 percent of the population of the United Kingdom lives in England; a quarter lives in southeast England, with some 7.5 million in London.

The United Kingdom is a highly developed country with the fifth-largest economy in the world and the second largest in Europe after Germany. Manufacturing and agriculture are far smaller segments of the British economy than they used to be, but a perennially important industry that places a significant demand on the road network is tourism. The United Kingdom is the sixth most popular tourist destination in the world. The energy sector is another important part of the economy. The United Kingdom has large coal, natural gas, and oil reserves. Nonetheless, gasoline taxes are among the highest in Europe, partly to control congestion on the motorways. Recently, London's municipal government took the controversial step of imposing a stiff tax on all vehicles entering the city during the workweek in an effort to reduce traffic congestion in the city center.

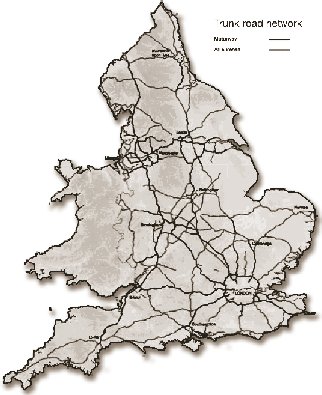

There are some 177,000 mi (285,000 km) of roads in the United Kingdom's roadway network, about 900 lane-mi (1,500 lane-km) of which are concrete pavements. The English portion of this roadway network is shown in figure 16; the road networks of Wales, Scotland, and Northern Ireland are not shown in this figure.

Figure 16: Network of motorways and all-purpose roads in England.

Until the early 1980s, JPCP and JRCP were the most common concrete pavement types built. From the mid 1980s to the mid 1990s, the typical concrete pavement construction was CRCP with a brushed surface. In the late 1990s, as a matter of public policy, thin hot-mix asphalt surfacing (see figure 17) came to be required on concrete pavements. This occurred because of public pressure on lawmakers to compel the Highways Agency to find a way to reduce noise from road surfaces. This Highways Agency prohibition on bare concrete road surfaces applies only in England, not elsewhere in the United Kingdom.

Figure 17: Thin asphalt surfacing mandated on concrete roads in England.

In the case of a public-private partnership project, the contractor may request a "departure from standards" and select any pavement type. The Highways Agency generally approves such requests because the contractor bears the risk. The typical requirement for PPP projects is that the roadway must be returned after 30 years with 10 years of remaining life. The Highways Agency does not have a protocol for how the remaining life in the 30th year is to be established. An asphalt overlay, for example, placed during that last year would very likely be considered to meet the requirement for furnishing 10 years of remaining life.

One of the first roadway improvement projects in the United Kingdom conducted as a public-private partnership was the widening of the A1(M) motorway between Alconbury and Peterborough. This DBFO contract, awarded in 1996, required the consortium of partners to finance the widening, operation, and maintenance of a 13-mi (21-km) section of the A1 motorway between London and Newcastle until 2026. The estimated construction cost was US$255 million (€128 million). In exchange, the consortium receives payments from the Highways Agency in the form of a "shadow toll" (roadway users do not pay tolls) computed as a function of the road's usage. The Highways Agency retains ownership of the road and has hired an independent consultant to act as the agency's representative in monitoring the construction, operation, and maintenance of the roadway.

The Highways Agency maintains a pavement management system for the United Kingdom's roadway network. Traffic data stored in the pavement management system is now limited to information on heavy commercial vehicles because the original focus of the pavement management system was pavement deterioration. Now, as operational issues gain importance, work is underway to improve the information on passenger car volumes in the pavement management system's database.

The Highways Agency operates the TRAC equipment for measuring longitudinal profile, the SCRIM device for measuring skid resistance, and a deflectograph for testing nondestructive deflection. Visual surveys of pavement condition are also conducted.

A computer program called SWEEP (software for the whole-life economic evaluation of pavements) is used for project-level maintenance treatment selection. A network-level analysis program has been under development for 7 years and for the last 4 years has been used to help generate the annual program of pavement investment and maintenance activities. This stand-alone, network-level analysis program was developed by the private-sector Transport Research Laboratory. It does not interact with the other modules in the Highway Agency's pavement management system software.

| << Previous | Contents | Next >> |