U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

The team found that the European host agencies visited valued their bridge inspection programs not only to ensure highway user safety, but also to ensure that durability and serviceability expectations were met and to enhance capital investment decisions on the existing bridge inventory. The agencies placed major emphasis on providing quality assurance through well-defined inspector qualifications, periodic calibration of inspectors, data collection processes, verification of data, and use of appropriate equipment to evaluate their structures. Nearly all of the agencies the scan team visited had major programs aimed at inspection uniformity and had developed a multitiered inspection program with procedures for performing damage assessment and programming maintenance and repair through the inspection process.

The scan team identified many bridge inspection practices and technologies related to the previously stated topics of interest. The items that the team believes could enhance bridge inspection practices in the United States are discussed in this chapter. The order in which they are presented is for clarity and does not reflect the priority recommended by the team.

In the countries the scan team visited, many detailed, heavily illustrated manuals and references were available as tools for bridge inspectors, including inspection manuals, maintenance guides, repair manuals, and coding and recording data guides. The primary approach in the United States and the European countries the team visited is visually based inspection. The host nations use visual aids to a greater extent in recording and coding of data, damage assessment, and maintenance and repair. Numerous manuals are available for inspection and maintenance. To focus inspectors and provide more uniform ratings, the types of damage with performance indices were quantified with accompanying photographs. These manuals contain many photos and drawings showing damage and corresponding rating levels.

The Finish Road Administration (Finnra) provides guidance in five documents:

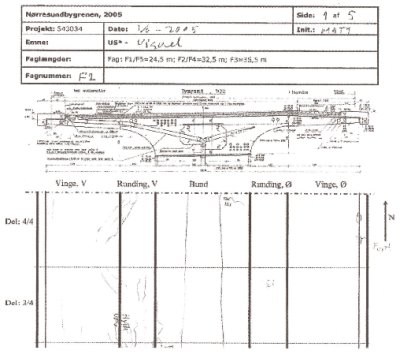

Two of these, the Bridge Inspection Manual and Guidelines for Bridge Inspection, guide field inspection activities for bridge inspections. The guidelines set out the procedures for gathering and checking the structural and damage data at the bridge site, as well as the methods for processing and using the accumulated data. The Finnra bridge inspection system is presented in the Guidelines for Bridge Inspection. Figure 1 illustrates the cover and two internal pages from this document. The Bridge Inspection Manual provides guidance for classifying and entering data in the bridge register, a database containing structural and condition data on Finnish bridges. Figure 2 shows the cover and two internal pages from this document.

Figure 1: Sample pages from the Finnra Guidelines for Bridge Inspection that include diagrams of how to perform inspections and typical structural details.

Figure 2: Sample pages from the Finnra Bridge Inspection Manual providing specific coding guidelines.

An interesting finding was that several countries had implemented standards to quantify concrete cracking in inspection reports. For instance, table 2 illustrates a scheme for classifying concrete cracking from the Finnra Bridge Inspection Manual.

The Finnish Road Administration has also issued standardized bridge repair directives in its Bridge Repair Manual (SILKO Guidelines) to standardize and guide repair work on bridges identified during the inspection process. These manuals and several data sheets are shown in figure 3. The stated goal of these manuals is to provide standardized repair scenarios for various types of damage to a bridge, to improve durability of a bridge, and to improve bridge construction and maintenance. Directives are issued for a wide range of items. An abbreviated table of contents listing the directives is in Appendix E.

Figure 3: Finnra's Bridge Repair Manual (SILKO Guidelines).

Each directive contains a detailed discussion on the structural element, applications and limitations, warrants for repair, equipment needed to make the repair, approved materials for use in making the repair, and job site needs and safety. The directives, issued as individual brochures for each repair directive, are maintained in a four-volume set. These directives are linked to the Finnish bridge management system (BMS) and, when repairs are made using the directives, a record of the repairs is entered in the bridge register. Finnra monitors the repair work and uses the information it obtains to improve guidance. Training on these manuals is viewed as essential. The training provides guidance to users on recommending repair methods and approving materials.

The Norwegian Public Roads Administration Handbook for Bridge Inspection provides a thorough explanation of condition ratings. The manual contains many photos showing damage and corresponding rating with both degree and consequence of damage. The handbook, prepared to cover the requirements of the staff involved in bridge inspections, provides thorough and detailed guidance on damage evaluation. Emphasis has been placed on explaining different types of damage to different types of structures using photos and explanatory damage evaluation guidance. The photos have been used extensively to facilitate a better understanding of the damage type.

| DAMAGE CLASS | TYPE OF STRUCTURE DAMAGE | SUPERSTRUCTURE | OTHER STRUCTURE | SPECIAL STRESS | ||

|---|---|---|---|---|---|---|

| Normal reinforcement | Prestressed reinforcement | Edge beam | Water level range | |||

| 1 | Crack width is under 0.2 mm. Cracks are small, mainly surface cracks. | A | A | - | B | - |

| 2 | Crack width is 0.2 to 0.4 mm. Cracks are small structural cracks, generally due to shrinkage. | B | C | B | B | - |

| 3 | Crack width is 0.3 to l.0 mm. Structural cracks are generally due to deflection, exceeding of the shear capacity, or creep. Cracks are generally found in the superstructure. | C | D | C | C | C |

| 4 | Crack depth is over 1.0 mm. Structural cracks are due to uneven settlement or a large deformation. Cracks are often serrated and generally found in the substructure. | D | D | D | D | D |

A. Surface treatment may be considered. A special inspection shall be undertaken to determine the degree of reinforcement corrosion as well as the chloride concentration and depth of carbonation. The surface treatment must be able to withstand minor structural deformation. A specification shall be drawn up.

B. The cracks in the upper surfaces are soaked using capillary action. Other cracks are injected as needed. A leaking crack must always be injected. A specification shall be drawn up.

C. A special inspection shall be undertaken to determine the cause of cracking. The cracks are injected using epoxy to restore original structural strength. Leaking cracks place special demands on the epoxy and the work method to be used. The effect of cracks on the condition of tendons in prestressed structures must be determined. A specification shall be drawn up.

D. The reason for cracking is determined through a special inspection. The cracks are injected using epoxy or cement slurry with filler added as needed. Calculations are used to determine the need for additional strengthening of structures and possible service limitations. A special inspection is carried out and a repair plan is drawn up. In the case of prestressed structures, the effect of the damage on tendons and cables must be determined.

The Federal Department of Transportation, Construction, and Housing's Office of Road Construction and Traffic (German Federal Ministry of Traffic, Building, and Urban Affairs) has issued two documents, DIN 1076: Engineering Structures in Connection With Roads-Inspection and Test and Directive for Uniform Determination Assessment, Recording, and Analysis of the Results of the Inspection of the Structures in Accordance with DIN 1076. These documents provide detailed guidance on documentation of inspection and testing performed during bridge inspections.

The scan team observed host nation inspectors with photographs from past inspections on site to use in current inspections. This practice allows the inspector to make more accurate observations of changes in bridge conditions since the last inspection. In Germany, digital photographs are imbedded in the final report, along with report text and associated sketches.

Inspection vehicles in Germany were fully able to support activities at the inspection site. A maintenance repair and rehabilitation specialized truck was modified to incorporate office workspace for the inspector that included a desk, a laptop computer (including inspection program SIB-Bauwerke), a reference library complete with all pertinent inspection references, and a complete set of bridge records for the bridges being inspected. The interior of one such vehicle is shown in figure 5. One example observed was a manual from a bearing manufacturer that provided specific inspection guidance for the inspector in the field. A locker is provided for tools and diagnostic and NDT devices necessary to perform an inspection to accepted standards. Storage space for personal safety equipment and boots is also provided. These inspection vehicles, along with other necessary access and safety vehicles, enable bridge inspectors to work in a variety of inspection scenarios and in remote areas for a prolonged period without dependence on other assets, thereby promoting efficient field activities.

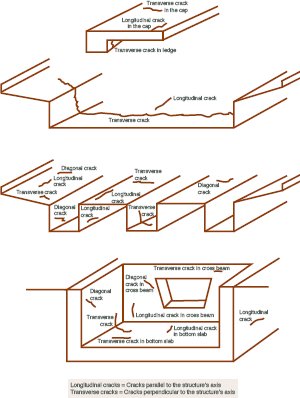

Figure 4: German federal guidance on describing cracks in superstructures.

All countries visited practice standardization of inspection reports, forms, terms, and ratings. Noteworthy practices included generating customized bridge inspection forms by bridge management systems, standardizing terms and rating criteria for inspectors, embedding digital photographs in inspection reports, and requiring designers to identify critical areas of a structure to be inspected. The inspector's recommendations are integrated into maintenance activities and are used to initiate agency actions to correct deficiencies identified based on recommended action, timing, and cost. The inspector, through various agency-established protocols, addresses critical needs.

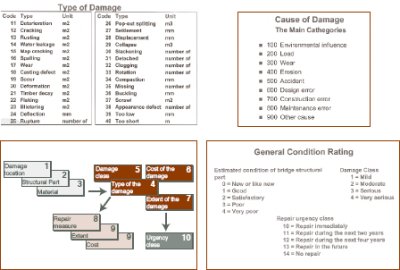

The coding of the type of damage, cause of damage, and condition rating is standardized in Finland's inspection guidelines (figure 6).

Finish bridge inspectors include the following minimum information in their written report:

Damage data are recorded by the inspector and include the following information:

Figure 5: Interior of German inspection vehicle showing conferencing workspace.

Figure 6: Finnra guidelines for coding condition, damage type, and cause.

Based on the inspector's field observations, repair recommendations are included as part of the inspection report. Recommendations include the following:

The inspector's recommendations are used to initiate agency actions to correct deficiencies identified based on recommended action, timing, and cost. The inspector, through immediate contact with Finnra, addresses critical needs.

In the Norwegian Public Roads Administration's bridge management system, BRUTUS, the inspector can generate tailor-made inspection forms for every bridge. BRUTUS also provides previous inspection results to assist the inspector in reporting changes in structural conditions since the last report. Digital photographs are used extensively in Norwegian inspection reports. Sketches are more rarely used and, if used, they are scanned and included as a digital image.

Paper copies of reports from special inspections are filed in a traditional filing system for bridges. Data from routine inspections are maintained electronically in BRUTUS. Reports are generated and printed from the system as needed. Repair and maintenance activities may be initiated by work orders prepared using BRUTUS as a result of inspection data provided. When the repair or maintenance is completed, it is possible to record the date, costs, name of contractor, and a brief description of the maintenance activity or to simply record the activity as accomplished.

In the field, the inspectors record a level of urgency for any required repair in their assessment of damage found. This level of urgency is used to determine annual fund allocations, program maintenance repairs, and track repair backlogs.

In Denmark, the existing bridge management system mainly targets the typical highway bridge or overpass structure. The management system has the ability to handle data for many structures. It includes data on typical components in a simply organized database. Separate asset management policies, systems, and practices have been identified as necessary for managing major structures to allow better decisionmaking for capital investments.

Figure 7: Standardized report form used by Danish firm Ramboll.

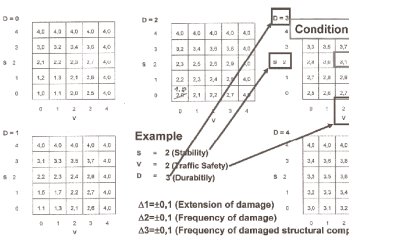

Figure 8: Calculation of Condition Index.

In Germany, a computer program, SIB-Bauwerke Release 2006, is in use. The program allows inspectors to select a structural condition from a pull-down menu that allows the program to generate a rating. The inspector is provided detailed guidance on assessing structural stability (table 3), traffic safety (table 4), and durability (table 5). Based on these ratings, the inspection program calculates a condition index for the structural element (tables 6 and 7), automating the assessment provided in the report.

| Damage Assessment "Structural Stability" | |

|---|---|

| Assessment | Description |

| 0 | The defect/damage has no effect on the structural stability of the structural element/structure. |

| 1 | The defect/damage negatively affects the structural stability of the structural element; however, it has no effect on the structural stability of the structure.

With respect to the as-planned utilization, individually occurring, small deviations in the condition of the structural element, the quality of the construction material, or the element's dimensions are still clearly within the scope of the admissible tolerances. Repairs to be carried out within the scope of regular maintenance. |

| 2 | The defect/damage negatively affects the structural stability of the structural element; however, it has little effect on the structural stability of the structure.

The deviations in the condition of the structural element, the quality of the construction material, or the dimensions or the as-planned stresses resulting from the utilization of the structure are still within the scope of the permissible tolerances. In individual cases, the admissible tolerances of the structural element may be exceeded. Repairs must be undertaken within the medium term. |

| 3 | The defect/damage does affect the structural stability of the structural element negatively; the deviations with respect to the condition of the structural element, the quality of the construction material, or the dimensions or the as-planned stresses resulting from the utilization of the structure exceed the permissible tolerances.

The required restrictions on the use are not in place or are ineffective. The damage must be repaired at short notice. Restrictions regarding utilization must be put in place immediately. |

| 4 | The structural stability of the structural element and the structure no longer exists.

Immediate measures must be taken during the inspection of the structure. Restrictions regarding the utilization must be put into place immediately. The repair or renovation must be initiated. |

| Damage Assessment "Traffic Safety" | |

|---|---|

| Assessment | Description |

| 0 | The defect/damage has no effect on traffic safety. |

| 1 | The defect/damage affects traffic safety only slightly; traffic safety is given. Repairs to be carried out within the scope of regular maintenance. |

| 2 | The defect/damage affects traffic safety only slightly; traffic safety, however, is still given. Repairs must be carried out or warning signs must be put up. |

| 3 | The defect/damage affects traffic safety. Repairs must be carried out or warning signs must be put up at short notice. |

| 4 | Due to the defect/damage, traffic safety is no longer given. Immediate measures must be taken during the inspection of the structure. Restrictions regarding the utilization must be put into place immediately. The repair or renovation must be initiated. |

| Damage Assessment "Durability" | |

|---|---|

| Assessment | Description |

| 0 | The defect/damage has no effect on the durability of the structural element/structure. |

| 1 | The defect/damage negatively affects the durability of the structural element; however, it has no long-term effect on the durability of the structure. An expansion of the damages or consequential damages to other structural elements is not expected. Repairs to be carried out within the scope of regular maintenance. |

| 2 | The defect/damage negatively affects the durability of the structural element and can, in the long term, also negatively affect the durability of the structure. An expansion of the damages or consequential damages to other structural elements cannot be excluded. Repairs to be undertaken within the medium term. |

| 3 | The defect/damage negatively affects the durability of the structural element and affects, in the medium term, the durability of the structure in a negative manner. An expansion of the damages or consequential damages to other structural elements can be expected. Repairs must be undertaken at short notice. |

| 4 | Due to the defect/damage, the durability of the structural element and of the structure is no longer given.

The expansion of the damages or consequential damages to other structural elements requires immediate repairs, restrictions on utilization, or a renovation of the structure. |

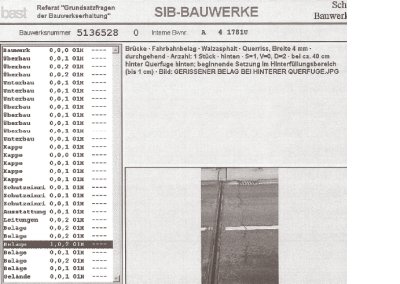

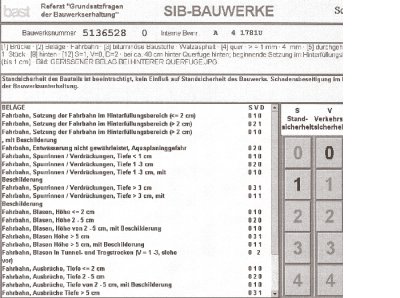

Damage assessment is aided by use of a detailed catalog of damage conditions contained in the software and available by keywords. A screen from the software showing cataloged damage to a bridge deck joint is shown in figure 9. An inspector has the ability to enter a rating not in the catalog, but a requirement is built into the software requiring justification for not using a standard. A screen from the software showing an inspector-generated rating page is shown in figure 10. There are now about 1,200 standards, and the number in the catalog was expected to grow to about 1,800 by the end of 2007. A permanent committee appointed to oversee this catalog reviews the ratings periodically to update it as required.

Another item of interest in European agencies is the practice of having senior office staff review a sampling of reports. Several agencies have processes for senior in-house inspectors' review and field check of reports submitted by junior inspectors and vendors.

The general practice of European agencies was not to use dedicated inspectors on bridges, but to rotate inspectors on subsequent inspections. This practice provides a fresh assessment of the bridge's condition.

Figure 9: Screenshot of SIB-Bauwerke Release 2006 showing cataloged damage to bridge deck joint.

| Grade | Description |

|---|---|

| 1.0-1.4 | Very good structural condition |

| The structural stability, traffic safety and durability of the structure are given. Continuous maintenance is required. | |

| 1.5-1.9 | Good structural condition |

| The structural stability and traffic safety and durability of the structure are given. In the long term, the durability of the structure may be negatively affected to a small degree. Continuous maintenance is required. | |

| 2.0-2.4 | Satisfactory structural condition |

| It is possible that, in the long term, the durability of the structure may be negatively affected. An expansion of the damage or consequential damages which, in the long term, would lead to considerable deterioration of the structural stability and/or traffic safety and increased wear and tear is to be expected.

Continuous maintenance is required. Maintenance is requred in the medium term. Measures to eliminate the damage or warning signs to maintain traffic safety might be necessary at the short notice. | |

| 2.5-2.9 | Unsatisfactory structural condition |

|

The structural stability of the structure is given.

Traffic safety might be negatively affected. The durability of the structure may be negatively affected quite a bit. An expansion of the damage or consequential damages which, in the medium term, would lead to considerable deterioration of the structural stability and/or traffic safety and increased wear and tear is to be expected. Continuous maintenance is required. Maintenance at short notice is required. Measures to eliminate the damage or warning signs to maintain traffic safety might be necessary at short notice. |

European countries use a variety of approaches to train and certify inspectors. All countries have technical education requirements for inspectors, and most require those who lead inspectors to have an engineering degree. Many have specialized training requirements for inspectors to ensure the quality of the inspection and the data provided. Specialized training at the program manager level and performance-based testing requirements were believed to be significant.

Maintaining a core of in-house staff with expertise in bridge inspection is a high priority for European owners. Experienced staff provides a cadre of personnel to act as trainers and certifiers of new staff and vendors, provide quality assurance reviews of work performed on behalf of the agency, and develop reference materials in support of agency programs.

In Finland, bridge inspector training is arranged by the Finnish Road Administration and involves a 3- or 4-day theoretical course of study with 1 day of onsite training. Training culminates in a 1-day performance evaluation involving inspection of a bridge and a written test. Finnra also provides a 2-day course in bridge register use that must be completed before an inspector is granted rights to update the data. Annually, inspectors are required to undergo a 1-day "calibration" involving a general inspection of two bridges, after which candidates receive the official results of the inspections and discuss them with the examiner. To maintain certification, inspectors not only have to pass the hands-on bridge inspection assessment, but are also subject to a QA check involving a bridge inspection with two other inspectors. The results of the three inspectors are then checked for consistency. Personal quality points are assigned to each inspector and used in the procurement process. Candidates who repeatedly have weak test results can lose their certification.

Candidates for certification must have at least 2 years of experience as a member of a bridge inspection team. The lead inspector on a team must possess a master of science degree in bridge engineering or civil engineering and have experience in design of load-bearing structures or repair and rehabilitation of bridges. Other personnel must be familiar with inspection methods and use of inspection equipment.

| Grade | Description |

|---|---|

| 3.0-3.4 | Critical structural condition |

|

The structural stability or traffic safety of the structure is negatively affected.

Possibly, durability of the structure is no longer given. An expansion of the damage or consequential damages may, in the short term, lead to the fact that structural stability and traffic safety are no longer given. Continuous maintenance is required. Immediate repairs are required. Measures to eliminate the damage or warning signs to maintain traffic safety or restrictions in its use might be required as soon as possible. | |

| 3.5-4.0 | Inadequate structural condition |

|

The structural stability or traffic safety is negatively affected quite a bit or is no longer given.

Possibly, durability of the structure is no longer given. An expansion of the damage or consequential damages may, in the short term, lead to the fact that structural stability and traffic safety are no longer given and that it will result in an irreparable deterioration of the structure. Continuous maintenance is required. Immediate repairs or renovations are required. Measures to eliminate the damage or warning signs to maintain traffic safety or restrictions in its use might be required immediately. |

Figure 10: Screenshot of SIB-Bauwerke Release 2006 showing inspector-generated rating page.

Norway matches complexity of bridge inspection assignments to in-house and consultant inspectors based on education and experience. The number of bridge inspectors is not high, so the person in charge of ordering the inspections should be aware of inspectors' qualifications. Norway bridge inspectors are also knowledgeable about bridge design and construction. Knowledge and experience in bridge design are considered more important than material knowledge, but knowledge of the material being inspected and degradation processes is also integral to the inspection process.

The Swedish Road Administration has requirements for inspection personnel on education, knowledge about regulations and materials, etc., but no formal requirement for certification. No physical qualifications are required, either. The choice of inspector is based on the information submitted in the procurement document, which provides special personnel requirements for the specific inspection. However, common basic requirements for inspectors are the following:

The Swedish Road Administration sets the requirements for bridge inspection on the national road network. Other bridge managers or owners in Sweden comply with the same requirements, but may adjust special requirements higher or lower at their discretion.

The same requirements apply to underwater inspectors as other inspectors. In addition, the Instructions for Diving by the National Board of Occupational Safety and Health apply. Further, the diving equipment must be inspected and approved and appropriate diver safety practices must be used during the inspection.

For special situations, nationally or internationally known experts in the field may be hired. Requirements are identical for both in-house staff and vendors. Inspector data are maintained in the BMS, BaTMan, which tracks every inspector's individual performance.

In France, qualification is targeted at the inspector and inspection or project manager through six modules of training. Individuals must pass an exam to qualify for a position in each level. The qualification procedure is part of the ISO 9001 quality process developed by the network of Ponts et Chaussées Regional Laboratories (Public Road and Bridges Laboratories) in the field of bridge, culvert, and retaining wall inspection. The 17 French laboratories perform inspections for the national network, departments, cities, and towns as consultants.

Private consultants also perform bridge inspection, and their activities will probably increase in the future.

Training modules are organized by the Ecole Nationale des Ponts et Chaussées and are open to public laboratories and private consultants. A questionnaire at the end of each module tests the knowledge acquired by the candidates. For the public laboratories, a minimum grade is required to validate the module.

The goals of the French inspection training modules and qualification process are as follows:

The course of qualification covers technical requirements only. Requirements for physical ability, health, and sanitary and safety conditions for inspectors are controlled by the director of the Regional Ponts et Chaussées Laboratory.

After a project manager makes a proposal, the training is delivered at the regional laboratory by the chief of the Bridge Service and, should the need arise, the director of the regional laboratory. Training is provided in six modules, the first five designed for bridge inspectors and the sixth required for project manager certification.

Modules 1 through 5 are as follows:

Module 6 is a 3-day project manager's course that includes the following:

There are three levels of qualification: inspection agent, inspector, and project manager. The director of the regional laboratory certifies inspection agents locally.

Higher levels of certification (as inspector or project manager) require certain prerequisites, including the following:

Certification of qualification as an inspector may be obtained two ways. The first is by completing at least module 1 of the training, passing a professional examination involving a bridge inspection with a statement of findings, writing a report, and undergoing review by an examining board. The second way is by undergoing a review of past experience (at least 5 years) acting as an inspector and review by an examining board. The qualification of the inspector may be extended with modules 2, 3, 4, and 5.

Certification of qualification as a project manager may also be obtained in one of two ways. The first is by completing modules 1 through 6 and passing a professional examination that involves checking a bridge report proposed by an inspector, writing the report conclusions, and undergoing review by an examining board. The second is by undergoing review of past experience acting as a project manager (at least 3 years) and review by an examining board.

Germany has no mandatory professional training for engineers conducting bridge inspections. The German standard DIN 1076 requires only that an experienced engineer perform construction inspection. The minimum requirements are a completed study at a university or a university of applied sciences (bachelor or master of civil engineering or science degree) and experience in bridge building or construction engineering. Physical ability to perform the tasks associated with the job is assumed.

The lack of mandatory training requirements is rooted in Germany's history. During the post-World War II years, reconstruction was a priority for the country. Confidence in the state of technology and the quality of the materials being used in bridge construction led to public confidence in the ability of bridges in service to operate for decades without incident.

Periodic inspection of construction was performed, but the practice of construction inspection did not have the importance it now has. This changed because of two events in 1976. The first was the failure of the Reichsbrücke, a bridge in Vienna, Austria, originally built from 1872 to 1876 and completely restored from 1934 to 1937. On August 1, 1976, the bridge collapsed because of substructure damage, killing one person. The last documented general inspection before the failure was in 1952, almost 25 years earlier.

Also in 1976, considerable damage was detected on prestressed concrete bridges in Düsseldorf. Cracks 4 millimeters wide in the area of the coupling joints and several broken prestressing tendons were found. This led to a wider investigation that determined that a large number of similar bridges had comparable damage. As a result, both practitioner and public views on the need for bridge inspection changed.

The initial effort went into improving construction inspection, which has developed to a very high quality standard of practice for bridge construction in Germany today. In 2000 the German Federal Ministry of Transport and the Road Administrations of the Federal States began an initiative to set up a professional development seminar for bridge inspectors. The purpose of the seminar was to establish a forum for the exchange of knowledge and experience among practicing bridge inspectors. The first of these 5-day courses took place in November 2002 at BASt in Bergisch-Gladbach.

From 2003 to 2005, 14 additional courses were held with 340 participants attending. The number of participants at each seminar was limited to 25. Seminar seats not occupied by employees of the road administrations could be allocated to interested engineers from the private sector, city agencies, waterway administrations, port administrations, and others.

Growing demand for this training required establishing two additional seminar locations at Feuchtwangen in Bavaria and the Bochum University of Applied Sciences in North Rhine Westphalia. A fourth location in Dresden was scheduled to begin offering seminars in 2007.

The following are prerequisites for seminar participation:

Staff at each site organizes the seminars, but seminar quality is ensured by a national coordinating committee. The coordinating committee consists of representatives of the German Federal Ministry of Transport, BASt, state road administrations, training locations, and a university lecturer. This body determines course content and speakers, coordinates scheduling, and oversees the quality of each seminar.

Seminar instructors are experienced bridge inspectors from the road administrations of the federal states. They are supported by speakers from BASt, German Materials Research Institute (BAM), universities, and private organizations, as well as by employees of municipal administrations.

An association, Verein zur Förderung der Aus- und Weiterbildung von Bauwerksprüfingenieuren (VFBI, or Association for the Support of the Training and Further Training of Building Inspectors), was scheduled to be formed in 2007. Association members will be bridge owners, including the German Federal Ministry of Transport, the Ministries of Transport of the Federal States, county and municipal agencies, and private companies. The intent is to integrate the coordinating committee into this association and ultimately turn the responsibility for inspector training over to VFBI.

After completing the seminar, attendees receive documents certifying their completion of the course. No examination is given before certification, although development of an examination is planned for the future. Anonymous tests are conducted, however, to assess quality of the training. While this certificate is considered in selecting consultants to perform bridge inspections, it is not required.

The following are also planned:

All of the countries visited had clear definitions of inspection types, but a major finding was that each country has several well-defined scopes for their inspections. A typical finding was that European agencies have developed a technical decisionmaking process for determining inspection frequency.

Usually included in this process is the competency of the inspection crew. Host nations visited believed that inspector qualifications and experience requirements by agencies as previously presented provided confidence in allowing inspectors to determine the duration between cycles of inspections, typically up to 5 or 6 years but up to 9 years in France. Denmark and France use risk acceptance criteria to help determine inspection type and frequency.

In establishing their programs, the host nations chose inspection intervals based on the amount of detail of their inspections, interim maintenance inspections, documentation, and qualifications of their inspectors. However, the host nations allow the inspection frequency of any individual bridge to be shorter (or perhaps longer in the case of France) than the set frequency or maximum frequency, based on factors related to inventory such as condition, size, structure type, age, average daily traffic, complexity, and robustness.

Inspections are conducted in Finland over the life of the structure are as follows:

Denmark conducts four types of inspections on its highway structures. The first is a road network inspection, which maintenance forces perform one to three times a week or when crashes or other highway incidents occur. Description of any damage found and photos are transmitted by phone or via the Internet directly to the engineer in charge of routine maintenance.

A routine maintenance inspection, performed at least annually, is a visual inspection conducted by Danish Road Directorate (DRD) staff. This type of inspection is performed when damage is estimated to be less than US$16,000. Repairs are handled as routine maintenance, and data on the activity are collected and stored in the Danish Road Directorate's bridge management system (Danbro).

Principal inspections are conducted every few months to every 6 years, depending on condition and the inspector's knowledge of the bridge. On average, these inspections occur every 5.5 years. The inspector determines frequency of inspection. This inspection, conducted by DRD staff, is mainly a visual inspection. Condition remarks, damage descriptions, and cost estimates are recorded in Danbro. This type of inspection is performed when damage is estimated to be more than US$16,000. As a result of a principal inspection, a special inspection may be ordered.

A special inspection is a more detailed inspection conducted to study a structure condition in more detail. Physical testing may be ordered as part of the inspection, including sampling of concrete, core drilling, and evaluation, and development of a more accurate cost estimate and estimate of duration to the next inspection. Special inspection reports typically provide two to four strategies to address structural needs.

The Norwegian Public Roads Administration performs inspections in a fashion similar to Sweden. Major inspections are conducted at least every sixth year and general inspections typically are done on an annual basis. The data collected include a description of any damage, photos, and a damage assessment. A repair recommendation with costs is also provided. The data are used to plan maintenance and, in some cases, to provide input for planned rehabilitation or replacement projects.

| The intention of our inspection system is to implement a risk-based inspection system in which the resources and the knowledge of the inspectors are optimized to fit every bridge. Bridges with short spans or total lengths and not crossing streaming water could be inspected less frequently than larger bridges, for instance; old bridges could have inspections more often; and so on. The responsible bridge engineer in every region could do this optimization within the limits given by the guideline.

-Norwegian Public Roads Administration |

In Sweden, two main kinds of inspections are performed for bridges: major inspection and general inspection.

The purpose of a major inspection is to identify and estimate damage that can affect the function or safety of a structure within 10 years. The purpose is also to determine damage that may lead to increased maintenance and repair costs if not repaired or maintained within 10 years. The major inspection is performed for all structural components, including those components underwater in daylight or equivalently lit conditions and from a distance of an arm's length. A major inspection is performed at least every 6 years. The inspector decides at the site when the next inspection shall be performed. It is important to emphasize that it is the condition of the bridge that is relevant for the frequency of the inspections. Deteriorating bridges are inspected more frequently.

The purpose of a general inspection is to follow up on damage identified during the last major inspection and repaired or corrected. Another purpose of the general inspection is to identify and estimate new damage that could lead to insufficient carrying capacity, traffic safety issues, or increased maintenance costs if not addressed until the next major inspection.

In addition to these two types of inspections, a special inspection may be routinely performed for mechanical and electrical equipment on movable bridges. Special inspections are also performed whenever a regular inspection has indicated a need to investigate in more detail a stated or presumed damage. Normally, only the specific damage or deficiency is investigated.

Other inspections include those performed by the contractor responsible for the maintenance contract for the segment of road containing the bridge. The purpose of these inspections is to identify damage that can affect traffic safety and the condition of the structure. Another purpose is to verify that the requirements of the maintenance contract are fulfilled.

In France, four types of bridge inspections are performed: routine visit, annual inspection, Image de la Qualité des Ouvrages (IQOA) evaluation inspection, and detailed inspection.

Maintenance forces make routine visits during their patrols of the highway system they are assigned.

Annual inspections are cursory, visual inspections intended to identify new, significant defects in structures and to program routine maintenance.

IQOA evaluation inspections, performed every 3 years, are more detailed visual inspections of structures. The purpose of this inspection is to classify the condition of bridges by IQOA class. The significance of this inspection is the classification, which is used to make decisions on capital investments to correct deficiencies identified by the inspector in the field. IQOA classes are outlined in figure 11.

Figure 11: IQOA grading scheme for bridge condition.

Detailed inspections occur every 3 to 9 years, but typically every 6 years, based on the inspector's recommendations. These are thorough visual inspections of bridges noting all defects. The detailed inspection is a brand-new inspection, often performed without reference to previous inspections, that establishes a bridge condition baseline to be used for inspections performed until the next detailed inspection is done.

Bridge inspections in Germany are defined as follows:

As the above description shows, there is great dependence on road maintenance supervisors to routinely monitor and report issues of structural condition in all of the countries visited. This practice greatly enhances the ability of the agencies to manage their bridge assets.

Another factor of interest was that European road agencies typically require inspection of structures starting at spans of 2 meters (6.5 feet), which includes many culverts and smaller structures in their management systems.

Finland had a unique approach to insuring quality. The Finnish Road Administration uses 106 bridges and 26 steel culverts as a control sample or set of reference bridges. This pool of bridges is statistically chosen as a representative sample of Finland's bridge inventory. Baseline data are gathered from these bridges by experienced in-house bridge inspection staff to provide consistency.

Data gathered are used to fulfill a variety of needs, including the following:

A reference bridge is categorized either as a structure exposed to seawater or deicing salt or as an "other" structure. Field tests performed on reference bridges include the following:

In addition to the above tests, additional lab tests are performed on samples removed from the structure as follows:

As stated above, Finnra uses these reference bridges and data from their inspections several ways. New information is harvested about bridge behavior and durability through these reference bridge studies that can be used for various purposes. Data are used to improve deterioration models for both the network-level and project-level BMS by model simulation with real data as mean values. The data are used to adjust deterioration models of bridge materials, as well as to provide structural and environmental information on a specific structure at the project level. The data are used for quality control by comparing baseline data with inspection data entered in the register for similar bridges and identifying any anomalies in those data.

The Finnish Road Administration certifies bridge inspectors annually. Inspectors are required to perform a general inspection of a number of bridges determined by the number of bridges the inspector proposes to inspect during the upcoming year (table 8). The inspector's resulting condition assessment is compared against ratings determined by Finnra staff. The chosen sample bridges will have been previously rated by Finnra with damage points to be coded by the examinee. Inspectors are evaluated on how their proposed condition ratings compare to condition ratings provided by in-house staff. This evaluation is also used to provide quality points for selection of consultant inspectors. If the examinee's scores exceed a set deviation range established by Finnra, an exception report is generated. Two quality parameters have been developed based on the examinee's deviation from the damage points of the nine main groups of structural members and the relative deviation from the sum of the repair cost of the bridge.

| Number of inspected bridges | Number of control inspections |

|---|---|

| 1-100 | 2 |

| 101-300 | 3 |

| >300 | 4 |

The results of these quality control inspections are used to determine personal quality points for an inspector. These quality points are then used in two ways of interest to the scan team. First, they are used as part of the Finnra procurement process to select bridge inspectors. Second, they are used to develop refresher training for inspectors when large differences from control ratings are noted.

Finland also has a defined QC/QA plan that is part of its agreement for consultant services.

During inspections, host nation bridge inspectors use nondestructive testing (NDT) to assist in their coding. Several agencies had detailed references outlining the appropriate use of NDT devices and methods, including terms and definitions, defects for which they are applicable, and, in Germany, independent evaluations of NDT products by users.

In Finland, appropriate use of NDT and sampling for lab testing is incorporated into the inspection process and also used during basic inspections and inspections of reference bridges. The extent of investigation and quality requirements for the following tests are outlined in Finnra's inspection guidelines:

The Norwegian Public Roads Administration's Handbook for Bridge Inspection provides specific guidance on tests used during various types of bridge inspections. The handbook provides specific guidance on tests to be performed based on such items as warrants for testing, type of inspection, bridge type, location and environmental conditions, and material being tested. The handbook gives more specific references to test procedures and protocols as appropriate.

The Germans have linked their inspection manual to a compendium, ZfP-Bau Kompendium, containing independently evaluated, available NDT methods that could be used during a bridge inspection. The compendium presents an evaluation of the various NDT methods available to end users and provides an independent opinion on the various items included. The compendium provides a detailed discussion on characteristics, applications, and evaluation of products. The report is a living document that allows updates as new items are evaluated.

The compendium was published in 1991 as BAM Research Report 177, Study of the Application of Nondestructive Testing Methods for Engineering Structures. The Germans had significant motivation for undertaking this effort. They found that knowledge about NDT methods was widely nonexistent and this lack of information was a major reason for not using NDT where appropriate. Further NDT training is not part of the engineering education of Germany's inspectors. Germany had a huge need, therefore, for an independent source of information about NDT to help inspectors determine which method to use for a given set of circumstances and to provide information on where the technology could be obtained.

The effort began in the late 1980s, when the work was first published as a Web document. Shortly thereafter, the Germans decided to create an interactive document, which is how the compendium exists today. The system is maintained in an expandable database, which allows for easy updating and generation of the compendium on a periodic basis.

As a result of the popularity of the compendium and the availability of the World Wide Web, an HTML version was created in 1997. The compendium was completely revised in 1999, and the latest revision was in 2004. The hypertext format allows for intuitive interaction and links to other sites. The compendium can be distributed in various media such as XML, as a printed text, as an electronic file, via the Web, or on CD for local use.

The Germans have identified several needed improvements. These include better marketing of the compendium as a useful tool for the inspection community; additional support from manufacturers, researchers, and end users; and willingness to share case studies, including successes and issues associated with the use of the NDT technologies in the compendium.

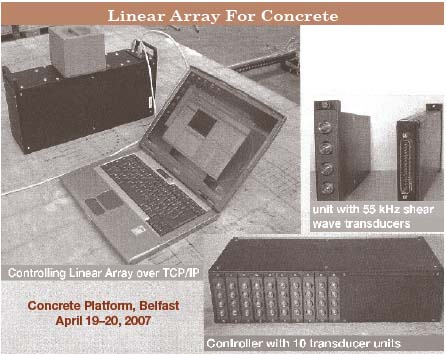

Several unique applications of NDT technology were available in Germany. One such device was a specially configured ultrasonic shear wave transducer (shown in figure 12) for use in identifying defects. This device consists of 10 units with ceramic tip, dry point contact 55 kHz shear wave transducers mounted in a controller. Each transducer fires sequentially over a period of 350 milliseconds, providing a reflected image of the interior of the element examined. When mounted on a robotic trolley or "stepper," developed by BAM, this device can be automated to provide an image across a length of deck or other element of interest.

Figure 12: Ultrasonic shear wave transducer.

BAM has developed several applications of scanning systems that allow measurements with NDT methods over large areas and with a high density of measurement points. It has used new tools available for data processing and visualization to improve the interpretation of resulting measurements obtained on concrete structures. Techniques developed to date allow the location and measurement of concrete structures up to 1.75 meters (5.7 feet) thick, tendon ducts up to 90 centimeters (35.4 inches) deep (including the location of tendon ducts in the second layer when ultrasonic echo is used), and nontensioned reinforcement using radar and grouting faults in tendon ducts.

A large concrete slab has been constructed in Germany for evaluating nondestructive evaluation (NDE) technologies. This slab includes embedded defects in the concrete (voids) and varying concrete thicknesses. The slab also includes post-tensioning ducts with grout voids of different characteristics. NDE methods intended to detect and quantify these embedded grout voids have been tested and evaluated. Advanced methods of scanning and imaging of NDE results have been developed using the slab, and a variety of acoustic and electromagnetic NDE technologies have been tested on the slab. Research has being conducted on fusion of data from different NDE methods to improve NDE capabilities. The slab has provided a test bed for researchers from around the world to evaluate and develop their technologies.

When possible, several agencies also use bridges scheduled for demolition to evaluate the effectiveness of NDT methods. NDT devices are used on these structures and data gathered are verified by actual field measurement during demolition or by lab tests off site.

Most of the agencies visited include a cause of damage investigation by the inspector as part of their bridge inspection procedure. Inspectors are trained to assess damage to a structural element based on structural stability, user safety, and effect on the damaged component's durability and recommend corrective action to address the damage. Using the inspector's knowledge of structures, coupled with a determination of urgency, an agency can calculate the immediate and short-term programming levels required.

The European agencies place a greater emphasis on determining the cause of a particular defect in the bridge. This is in contrast to the U.S. approach of characterizing the element or component, which essentially characterizes the effect of the defect. As a result, there is a greater integration of mitigation strategies (i.e., repair and rehabilitation activities specified by the inspector).

All agencies had procedures that would initiate actions based on the severity of the condition found, with or without a higher level of review and approval. In all cases in which critical structural conditions are found, immediate needs are addressed by immediate contact with the individual responsible for the facility, thus insuring public safety and protection of the facility from additional damage. Several other owners have procedures to initiate maintenance activities at the direction of the inspector.

One example of guidance provided to inspectors in making a level of urgency recommendation was found in Finland. The damage severity and a structural element's estimated condition are classified on a scale from 0 (no damage) to 4 (serious damage), according to guidance given in Finnra's Bridge Inspection Manual. The damage's repair urgency is to be described by Finish inspectors as follows:

The Bridge Inspection Manual recommends repair measures for each damage class and type of structure. The inspector is to make a recommendation for a repair measure based on his or her judgment of the observed damage to a bridge or element.

Another example was found in Sweden. The Swedish Road Administration (SRA) holds the inspector responsible for describing the condition of the entire structure, forecasting the deterioration rate, and proposing a suitable remedial action. SRA believes this is an extremely successful practice because the whole structure (i.e., all components) is systematically assessed during the inspection. It also requires that inspections involving several distinct evaluations (main inspection, steel inspection, underwater inspection, etc.) be completed in a relatively compressed timeframe to provide for the best possible overall assessment of the structure.

The scan team found that host country agencies generally tracked maintenance activities in their bridge records. This provided better management data on actual bridge conditions as well as costs associated with a structure.

An additional item of interest the team identified for consideration in the United States was a German DVD, "Inspection According to German Industrial Standard (DIN) No. 1076." The DVD is intended for viewing by the general public and outlines the reasons for bridge and structure inspection. The DVD not only provides an informative overview of the inspection process, it also was reported to be a useful mechanism for maintaining support for bridge inspection activities from its audience.

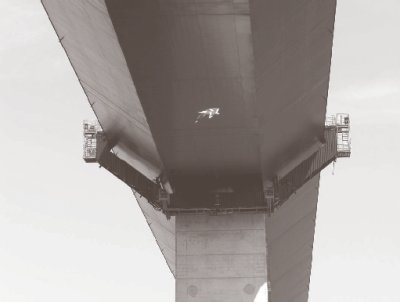

During bridge inspection site visits, the team observed bridge details incorporated in the design process to facilitate bridge inspections. At the Great Link Bridge in Denmark, elevators allowed easy access to the towers. Inspectors used a monorail inside the tub girder to move through the structure and transport inspection equipment. A permanent traveler, shown in figure 13, was installed for inspection of the structure's exterior. In Germany, concrete steps were built along the wing wall to allow for safe traverse of the side slope. A measuring system integral with the bearing was used to determine bearing displacement. Also, the pier cap at the expansion end was designed to allow access to inspect the post tensioning anchor block and modular joint. These details would also be helpful in performing bridge maintenance activities.

Figure 13: Permanent traveler on Great Link Bridge to provide inspection and maintenance access to underside of superstructure.

Based on the above findings, the team identified six primary topic areas for implementation:

The scan team has developed a detailed implementation plan for the recommended initiatives and practices. Included in the plan are a number of technical presentations and papers at national meetings and conferences sponsored by FHWA, AASHTO, and other organizations to disseminate information from the scan. Also included in the plan is coordination with AASHTO and FHWA to advance these initiatives and practices, including assisting with the development of new FHWA and AASHTO standards and guidelines governing quality in bridge inspection. These and other planned activities are discussed in Chapter 3.

| << Previous | Contents | Next >> |