U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

The asphalt industry and its agency partners are constantly looking for ways to improve pavement performance, increase construction efficiency, conserve resources, and advance environmental stewardship.(1) One such technology, now under evaluation, is warm-mix asphalt (WMA). WMA represents a group of technologies that allow a reduction in the temperatures at which asphalt mixes are produced and placed. These technologies tend to reduce the viscosity of the asphalt and provide complete aggregate coating at lower temperatures. WMA is produced at temperatures 20 to 55 C° (35 to 100 F°) lower than typical hot-mix asphalt (HMA). The same mechanisms that allow WMA to improve workability at lower temperatures also allow WMA technologies to act as compaction aids. Improved compaction or in-place density tends to reduce permeability and binder hardening due to aging, which tends to improve performance in terms of cracking resistance and moisture susceptibility.

WMA technologies also have the potential to be beneficial during cold-weather paving or when mixtures must be hauled long distances before placement. The smaller differential between the mix temperature and ambient temperature results in a slower rate of cooling. Since WMA can be compacted at lower temperatures, more time is available for compaction.

Fuel prices have risen sharply in recent years. It is estimated that if production temperatures are reduced by 28 C° (50 F°), fuel consumption to heat and dry the aggregate will be reduced by 11 percent.(2) Theoretical calculations for one WMA technology, with resulting mix temperatures less than 100 °C (212 °F), indicate a more than 50 percent reduction in fuel consumption to heat and dry the aggregate.(3)

Worldwide, one of the driving factors in the reduction of carbon dioxide (CO2) and other so-called greenhouse gases is the Kyoto Protocol, adopted by a consensus of the third session of the United Nations Framework Convention on Climatic Change. The Kyoto Protocol is designed to arrest greenhouse gas concentrations that some believe cause global warming. The Kyoto Protocol seeks to cut the production of CO2 by 5.2 percent of 1990 levels between 2008 and 2012. The European Union (EU ) has pledged a 15 percent reduction in CO2 emissions by 2010. Germany pledged a 25 percent reduction of 1990 levels, which was achieved in 2005.(4)

Although the United States has signed but not ratified the Kyoto Protocol, emissions reduction requirements are occurring through other legislation. In March 2005, the U.S. Environmental Protection Agency issued the Clean Air Interstate Rule (CAIR), which is designed to significantly reduce sulfur dioxide (SO2) and nitrogen oxide (NOx) emissions in 28 eastern States and the District of Columbia. SO2 and NOx contribute to the formation of fine particles and NOx contributes to the formation of ground-level ozone, both of which are associated with a variety of health problems. At full implementation, CAIR will reduce SO2 by 73 percent from 2003 levels and reduce NOx by 61 percent of 2003 levels. The greatest percentage of these reductions is expected to come from power plants.(5) Figure 1 shows the U.S. States covered by CAIR . Even before CAIR , some State and local regulations required that HMA plants in some nonattainment areas curtail operations during daylight hours during certain times of the year when ozone formation is problematic, or limit production to a certain number of hours per week.(1)

Figure 1: States covered by CAIR.

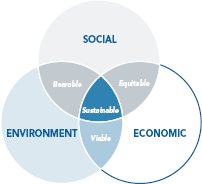

The concept of sustainable development embraces reduced consumption of raw materials (fuel), reduced emissions, and the possibility of increased recycling while still meeting development needs. The United Nations' Brundtland Commission defined sustainable development as "development that meets the need of the present without compromising the ability of future generations to meet their own needs."(6) Sustainable development does not focus solely on the environment, but encompasses three interdependent areas: economic development, social development, and environmental protection, as illustrated in figure 2. Both corporations and government agencies in Europe have embraced sustainable development. WMA is consistent with the ideals described by sustainable development.

Figure 2: Sustainable development.

Improved working conditions when placing HMA can lead to higher quality work, increased productivity, and greater employee retention. The implementation of engineering controls on asphalt pavers in 1997 was an important step in this direction.(7) Engineering controls remove fumes from the immediate area surrounding the paver and the screed operator. Reductions in HMA temperature reduce the fumes workers are exposed to and provide a cooler working environment.

WMA originated in Europe in response to a variety of concerns. In 2002, the National Asphalt Pavement Association (NAPA) led a study tour to Europe to examine WMA technologies. Since then, interest in these technologies has grown in the United States. The Federal Highway Administration (FHWA) designated WMA as a focus area.(8) FHWA and NAPA formed a WMA Technical Working Group to oversee WMA investigations and field trials in the United States. Research agencies such as the National Center for Asphalt Technology and other universities have conducted laboratory investigations of WMA. A number of State agencies and even some municipalities have placed trial sections of WMA in the United States.

As a continuation of the evaluation process, the American Association of State Highway and Transportation Officials (AASHTO) and FHWA organized a scanning study of Europe, allowing U.S. experts to meet firsthand with the agencies that first used these technologies, the suppliers and contractors that developed them, and the contractors that build WMA pavements. The study also allowed the team to view the performance of some of the oldest WMA projects in Europe.

In May 2007, a team of 13 U.S. materials experts visited four European countries-Belgium, France, German, and Norway-to assess and evaluate various technologies for reducing the temperatures at which hot-mix asphalt (HMA) is mixed and compacted. The scan team represented a wide variety of HMA interests in the United States, including AASHTO representatives from State agencies, FHWA representatives, asphalt supplier and HMA contractor industry representatives, and a consultant.

The purpose of the scan was to gather information on technologies used to produce WMA, with particular emphasis on long-term field performance. The scan team identified the following specific topics of interest pertaining to the use of WMA in Europe:

The team learned about a wide range of technologies, discussed with various agencies how and why they were implementing these technologies, visited construction sites, and viewed in-service pavements. In addition, the team tried to understand how conventional HMA practice differs between the United States and the various European countries and how these differences might affect potential WMA implementation in the United States. The information obtained during the study identified several implementation items to further the use of WMA in the United States. This report describes the scan, the team's findings, and its recommendations to help forward WMA as a viable alternative to HMA in the United States.

The WMA scan team was made up of State agency AASHTO representatives, FHWA representatives, asphalt supplier and HMA contractor industry representatives, and a consultant. The team members were John Bartoszek (Payne and Dolan Inc.), Gaylon Baumgardner (Ergon, Inc.), Matthew Corrigan (FHWA), Jack Cowsert (North Carolina Department of Transportation (DOT)), cochair John D'Angelo (FHWA), cochair Eric Harm (Illinois DOT), Thomas Harman (FHWA), Mostafa (Moe) Jamshidi (Nebraska Department of Roads), H. Wayne Jones (Asphalt Institute), David Newcomb (National Asphalt Pavement Association), Ron Sines (P.J. Keating Company), and Bruce Yeaton (Maine DOT). The report facilitator was Brian Prowell (Advanced Materials Services, LLC). Appendix A contains contact information and biographies of the team members. Figure 3 is a photograph of the team taken during a visit to the Colas Campus near Paris, France.

Figure 3: Scan team members (left to right) R. Sines, M. Corrigan, W. Jones, J. D'Angelo, D. Newcomb, T. Harman, E. Harm, B. Yeaton, B. Prowell, M. Jamshidi, G. Baumgardner, J. Cowsert, and J. Bartoszek.

The WMA scanning study began in November 2006 with the completion of a desk scan. The purpose of the desk scan was to review the use of WMA in a number of countries and identify the countries that would provide the most information about WMA technologies, construction practices, and field performance that could be implemented in the United States. The desk scan recommended that the team visit Belgium, France, Germany, and Norway during the study. While other countries have used WMA, France, Germany, and Norway have had the most long-term experience with WMA. Belgium was included to allow a visit to the European Asphalt Pavement Association to gain an overall perspective of WMA and HMA practices in Europe. The initial team meeting took place in November 2006 to identify critical issues to address during the scan and to develop a list of amplifying questions to give the host countries in advance. The amplifying questions, in Appendix B, were intended to help the host countries determine whom to invite to the meetings with the U.S. contingent and what to present to the group.

The team had an initial meeting in Washington, DC, to plan the scan trip countries and determine the emphasis areas. During the 2-week scan, the team visited representatives in four countries: Belgium, France, Germany, and Norway. After the scan, the team met to review the final report and implementation plan. Table 1 summarizes the team meetings and travel schedule.

| Date | Location | Purpose or Host |

|---|---|---|

| November 14, 2006 | Washington, DC | Initial team meeting to determine emphasis areas and develop amplifying questions |

| May 20, 2007 | Oslo, Norway | Kickoff trip meeting to review travel plan and make note-keeping assignments |

| May 21-22, 2007 | Oslo, Norway | Meet with Norwegian hosts |

| May 23-25, 2007 | Cologne and Frankfurt, Germany | Meet with German hosts |

| May 27, 2007 | Paris, France | Midtrip meeting to review findings to date |

| May 28, 2007 | Brussels, Belgium | Meet with Belgian hosts |

| May 29-June 1, 2007 | Paris and Nantes, France | Meet with French hosts |

| June 1, 2007 | Paris, France | Final trip meeting to identify key findings and develop preliminary recommendations |

| August 28-29, 2007 | Washington, DC | Final team meeting to finalize report and implementation plan |

During the scanning study, the team members met with representatives of about 25 organizations representing a broad range of asphalt pavement stakeholders. The majority of the organizations represented one of the following perspectives: road agency (city, regional, or national), contractor, supplier, academic, or industry association, as indicated in table 2. Lists of individuals the team met with and contact information are in Appendix C. The team participated in meetings and viewed in-service WMA pavements, plants producing WMA, and placement of WMA. The team members also interacted with their hosts on an informal basis during hosted dinners. The sites the team visited are listed in table 3.

| Type of Agency | Country | |||

|---|---|---|---|---|

| Norway | Germany | Belgium | France | |

| National or regional road agency | X | X | X | |

| Local road agency | X | |||

| Contractor | X | X | X | X |

| Supplier | X | X | ||

| Industry association | X | X | ||

| Academic | X | |||

| Country | Sites Visited | Location |

|---|---|---|

| Norway | Offices of Norwegian Public Roads Administration Kolo Veidekke asphalt plant and paving site Kolo Veidekke central laboratory and offices Various in-service pavements |

Oslo Ås Ås |

| German | German Federal Highway Research Institute (BASt) Wilhelm Schütz Co. asphalt plant |

Cologne Frankfurt |

| Belgium | Offices of European Asphalt Pavement Association | Brussels |

| France | Central Laboratory for Roads and Bridges (LCPC) Ministry for Transport, Infrastructure, Tourism, and the Sea, Highways General Department (DGR) EIFFAGE Travaux Publics asphalt plant FAIRCO paving site Routes de France (USIRF) Colas Campus (Research and Development Laboratories) Eurovia paving site |

Nantes Paris Near Paris Near Paris Paris Magny-les-Hameaux Near Paris |

The team members learned about many technologies, practices, and experiences during the scan. At the end of the 2-week trip, the team met to review its observations and findings and to develop recommendations for potential implementation in the United States. The benefits of WMA are described in Chapter 2. Chapter 3 provides an overview of WMA technologies and production practices. Chapter 4 covers the performance of WMA. Chapter 5 covers methods European countries have used to specify WMA. Chapter 6 covers the team's general observations on European mix design, construction, and contracting practices. Challenges that need to be addressed for successful implementation in the United States and recommendations for implementation are interspersed throughout Chapters 2 through 6 and summarized in Chapter 7.

| Contents | Next >> |