U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

PDF Version (0.8 mb)

Transportation and law enforcement agencies in the Netherlands have developed a robust weigh-in-motion (WIM) data management system that supports a broad array of vehicle weight regulation and enforcement activities, as well as long-term planning and decision-making. The system, which Dutch officials describe as "a better way of doing business," has potential for application in U.S. states that want to expand their use of WIM data.

U.S. transportation agencies have long recognized the application potential for WIM data, but few use the data to their full extent. Many limit the use of WIM data to support of pavement infrastructure design and prescreening of commercial vehicle weight for enforcement efforts. WIM data can also be useful in bridge structural analysis, geometric design, safety analysis, traffic control and operations, freight management and operations, facility planning and programming, and standards and policy development.

The Netherlands' WIM data management system was developed by the Centre for Transport and Navigation of the Ministry of Transport, Public Works, and Water Management (www.verkeerenwaterstaat.nl/english), in partnership with the National Police Services Agency (www.politie.nl/KLPD) and the Ministry's Inspectorate of Transport and Water Management (www.ivw.nl). A team of U.S. transportation experts observed the system during the 2006 Commercial Motor Vehicle Size and Weight Enforcement Scanning Study, sponsored by the Federal Highway Administration, American Association of State Highway and Transportation Officials, and National Cooperative Highway Research Program. The Dutch have integrated extensive quality control and quality assurance protocols into their system, significantly enhancing confidence in the vehicle information provided. This technical brief describes how WIM data are captured, processed, stored, reported, and used to support vehicle weight regulation and enforcement in the Netherlands.

In the late 1990s, the Dutch developed an innovative WIM and video system, WIM+VID, which has been integrated into routine commercial motor vehicle size and weight enforcement activities. Six WIM+VID sites were in operation on major roadways leading to and from the Port of Rotterdam in 2006 with two more sites approved for implementation.

Each WIM+VID site is equipped with a double row of Kistler Lineas™ piezo-quartz WIM sensors in the right two lanes, two cameras on each side of the road to capture the vehicle image, and cameras above each lane to capture license plates. Inductive loops and cameras in the third lane and right shoulder detect bypassing vehicles. Digital color and monochrome images of the complete vehicle are provided in daylight and at night, respectively. Infrared illumination allows effective capture of nighttime images.

Proximity and layout of WIM+VID Sites in the Netherlands

|

|

Specific data elements the WIM+VID system captures include vehicle classification, vehicle length, axle weight, gross vehicle weight, and vehicle speed. Vehicle classification data the system captures generally have error rates of 2 to 4 percent. Error rates for axle weights and speed generally do not exceed plus or minus 15 percent and plus or minus 2 percent, respectively, for 95 percent of the vehicles measured (in aggregate).

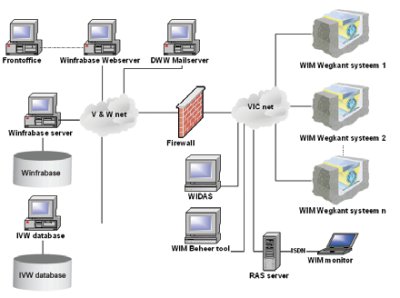

Following the WIM+VID data management system architecture, data from each WIM+VID site in the Netherlands are sent to the National Traffic Information and Communications Network (VIC-Net), the Ministry's internal roadside data communication network that links data from all systems implemented along the motorways. The WIM Management Tool (WIM Beheer Tool) supports management of the WIM sites, and the WIM Data Access System (WIDAS) is an interface for collecting vehicle data from the sites. The WIM roadside systems perform several data processing activities, which include isolating license plate images from raw camera images, analyzing axle/vehicle weight measurements, filtering data using predefined threshold or decision-rule limits, integrating static weight data to perform quality checks for WIM system calibration, and producing vehicle registrations. The National Police access these data through laptop computers (WIM monitors) and remote, secure access to support real-time preselection of noncompliant vehicles. The Ministry of Transport's internal data communication network, separated from VIC-Net by a firewall, allows for integration of the WIM+VID data with other internal databases, including a pavement management/construction materials database (Winfrabase) and the database maintained by the Transport Inspectorate.

Data Management System Architecture

Sample Quality Assurance Statement |

Internal to the Ministry of Transport, WIM+VID data can be accessed directly through the Ministry's V&W Intranet. The Cognosa™ Business Intelligence reporting tool allows Ministry of Transport personnel to extract personalized WIM data reports, nonfiltered or filtered according to vehicle size, vehicle weight, vehicle weight compliance status (i.e., compliant/noncompliant), vehicle class, or other, depending on need. A small staff, responsible for managing and maintaining the WIM data management system, is available to provide one-time or subscription reports to colleagues inside and outside the Ministry. The Ministry of Transport's Centre for Transport and Navigation relies on these data to conduct research and analyses, provide technical assistance, and offer policy recommendations on traffic and transport. External to the Ministry of Transport, WIM+VID data are provided via e-mail or CD-ROM in a variety of formats, including Excel, PDF, XML, and HTML.

To ensure that the available WIM+VID data are of sufficient quality, a two-stage assurance process is followed. First, a series of filtering processes is used to identify potentially unreliable, extreme, or unreasonable data records (e.g., speed records less than 60 kilometers per hour (km/h) (37 miles per hour (mph)) or greater than 120 km/h (75 mph), vehicle length records greater than 50 meters (164 feet), or axle loads greater than 30 metric tons (66,139 pounds)). Typically, less than 2 percent of data is identified as errant using these filtering processes.

In the system's second quality assurance stage, axle weight records captured by the WIM+VID system are directly compared for accuracy to the static axle weight records obtained by the National Police during scheduled enforcement activities for the same vehicles. If an unacceptable level of WIM+VID data error is observed (WIM+VID axle weight error rates usually do not exceed plus or minus 15 percent for 95 percent of the aggregate axles measured), a deviation can be corrected quickly through system correction or other remedial action such as calibration or sensor replacement. These checks are performed weekly, monthly, or when required. An output of this process is a formal quality assurance statement that includes the number of axles measured and compared to static weights, the period of measure, and the inaccuracy in aggregate and for every weight record. Quality assurance statements accompany every data report, including routine data disseminations to the National Traffic Police and Transport Inspectorate. This quality assurance statement allows data users to determine the sufficiency of data quality based on their individual needs.

|

Real-time Preselection

|

The use of WIM+VID data to support long-term planning and decision-making activities is limited only by the scant deployment of systems across the roadway network. The Ministry of Transport plans to expand WIM data applications in roadway planning, management, design, and maintenance as more systems are deployed. Potential future applications include the nationwide monitoring of noncompliant vehicles, compliant vehicles (i.e., general goods movement), and vehicles transporting dangerous goods. To date, however, the Dutch have focused on maximizing the use of WIM data for enforcement-related applications.

In the United States, WIM systems are often used in conjunction with fixed-scale facilities for real-time preselection (i.e., prescreening) of noncompliant commercial motor vehicles. Relying on mobile rather than fixed operations, the Dutch use a similar approach. National Police personnel at a mobile enforcement site receive data and video information from an upstream WIM+VID site. Within 15 seconds, overweight determination is made. The officer at the mobile enforcement site contacts on-road colleagues to intercept the overloaded vehicle and escort it to the downstream mobile site for further inspection. Onsite, the truck's individual axles are weighed using static scales and modest registration and safety checks are performed. An official report is issued if the vehicle is confirmed to be overweight or in violation of other regulations.

This technology-based approach has been credited with increasing officer efficiency (i.e., the number of citations issued compared to the number of vehicles stopped) from about 40 percent to more than 80 percent. The trucking industry traveling in and through the Netherlands is reacting to these preselection controls positively by investing in new vehicle configurations with additional lightweight axles and in-vehicle weighing systems to better self-monitor loading behavior. Hence, a reduction over time in the amount and frequency of weight overages suggests benefits from these enforcement efforts. Similar U.S. enforcement efficiency gains could be realized using WIM+VID systems and mobile enforcement teams in areas with no fixed-scale facilities (e.g., bypass routes).

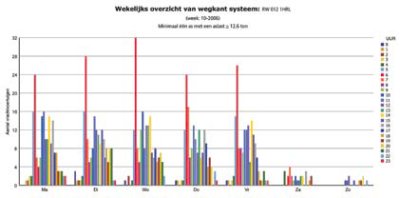

MoWIM report Overloaded Vehicles by Day of the Week and Section of the Day |

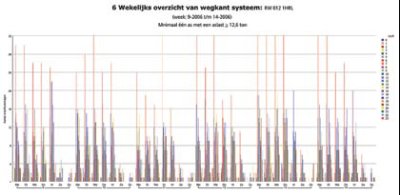

Continuing to focus on enforcement personnel efficiency, the Dutch use historical WIM+VID data to identify the time of day, day of the week, and location of high overweight vehicle activity and subsequently schedule mobile enforcement activities. The National Police receive the reports, which are automatically generated each Wednesday for each WIM+VID site and which provide an overview of overloaded vehicles per hour by day of the week and hour of the day for the most recent week and six weeks. The clear, concise design of these reports allows enforcement administrators to readily determine the most productive scheduling and dispatch of resources. These reports are accompanied by a quality assurance statement, described previously. These reports are also distributed weekly to the Ministry's WIM system managers and the Transport Inspectorate for informational purposes.

In the United States, select states employ a similar process to better direct mobile enforcement activities. For example, the Montana Department of Transportation uses the Measurement of Enforcement Activity Reporting Software (MEARS) to identify the time of day, day of the week, and location of high overweight vehicle activity, as well as the predominant types of noncompliant vehicles. Despite the potential gains in enforcement efficiency, this application of WIM data to support mobile enforcement scheduling is not yet widespread in the United States.

The advent of the WIM+VID systems has allowed the Transport Inspectorate to shift focus from roadside inspections to preventive contacts with habitually noncompliant carriers. In its view, preventive visits are more efficient than roadside inspections; a single contact can reach an entire company rather than a single driver or vehicle. In addition, application of the WIM+VID system for preventive visits allows for 100 percent capture and review of overloads (i.e., 24-hour-a-day, 7-day-a-week monitoring); roadside inspections are effective only when enforcement officials are present.

Overloaded Vehicles by Day of the Week and Hour of the Day

|

Sample Reports from Measurement of Enforcement Activity Reporting Software |

Using historical data from the WIM+VID systems (provided daily from each WIM+VID site), the Inspectorate reviews data on a monthly basis to determine offending vehicles and their companies. WIM sensors provide the weight-related information and the video image of the license plate and truck provides the company identifier. Once identified, the Inspectorate can access additional information (i.e., special transport permits).

Up to 50 transport companies with the highest monthly offenses are categorized as Code Red and receive special attention. The Inspectorate arranges a visit to the place of business to review the violation history, describe the WIM+VID system, discuss how overloads may be caused, and reach agreement to cooperate to prevent future overloading. Following the onsite visit, the transport company begins a 2-month monitoring period for compliance. The company receives an overview of performance twice during this period.

If a positive change in loading behavior is observed (a decrease in overload offenses of at least 75 percent), the company is recategorized from Code Red to Code Yellow, indicating that the company will still be monitored but not as intensely as before. If the behavior remains positive, the company is returned to Code Green with all other compliant companies and receives a written notification of its status. A list of companies for which no positive change in loading behavior is observed is sent to police personnel, who will stop all company vehicles, loaded or empty, for further inspection through the roadside enforcement process. For particularly problematic companies, scales may be placed at the company's entrance/exit to ensure no overloaded vehicles are released from the facility.

A similar educational rather than repressive approach to correct noncompliant behavior would likely be well received by both the enforcement community and the trucking industry in the United States.

Ensuring that intended legally permitted oversize/overweight vehicles are in fact "legal" poses a challenge in the Netherlands. The Transport Inspectorate used data from the WIM+VID systems for a pilot to monitor special transports. For this application, registrations of vehicles commonly used for special transports were checked with issued permits for these vehicles and the specific special transports.

From this desk data review, an estimated 40 percent of special transport trucks were observed to be operating without proper credentials, prompting the Transport Inspectorate to initiate a similar preventive contact approach for this segment of the industry. The Inspectorate relies on the same WIM+VID data to produce the annual Inventory Exceptional Transport report, which describes the volume and characteristics of special transport activity in the Netherlands.

Special Transport Monitoring

To achieve this level of WIM data utility, including the concomitant confidence in data quality, the Dutch have addressed many developmental challenges, both technical and organizational. Technical challenges relate to the installation and durability of WIM sensors in the field (attributable partly to the porous asphalt design of Dutch roads), the integration of the various system components supporting the WIM data management system, the security and management of different data networks, and the conversion of data formats to support various and diverse applications. Organizational challenges relate to unique agency priorities, cultures, and approaches and privacy restrictions on data collected and exchanged. Ministry of Transport, National Police, and Transport Inspectorate personnel expended significant initial effort to ensure that these organizational challenges did not hinder development of the WIM data management system.

Future WIM+VID Sites |

Future developments for the WIM data management system include an expanded WIM+VID network to support more diverse data applications (e.g., nationwide monitoring of noncompliant vehicles, compliant vehicles and general goods movement, and vehicles transporting dangerous goods). Funded through the Ministry of Transport, WIM+VID system installations are prioritized and must compete with other transportation needs of the nation. By 2006, six WIM+VID systems were operational, with two additional sites under construction. The Dutch envision a much more comprehensive network of WIM+VID systems, with more than 30 sites along key motorways.

A second area of development focuses on continued enhancements to proven data applications related to commercial motor vehicle regulation and enforcement. A recent cooperative effort called the Business Intelligence Monitoring WIM (MoWIM) Project aims to enhance mechanisms for assimilating, monitoring, and mining WIM+VID data and generating guiding reports to improve the effectiveness of enforcement efforts and meet objectives to reduce overloads by 20 percent per year on the national highway network (in the proximity of WIM+VID systems only). This project considers total gross vehicle weight and axle overloads by month, by WIM+VID site, and by vehicle type to direct officer-based selection procedures and the number and outcome of static measurements per employee per week, month, and location.

A recent project seeks to enrich the WIM data with two new vehicle-based indicators: (1) a vehicle damage indicator that would help direct preventive enforcement efforts based on the degree of overloading and the frequency of travel (i.e., comparative damage from a company making 10 trips with each vehicle exceeding 10 percent axle weight or two trips with 20 percent exceeding axle weight); and (2) a vehicle loading indicator (i.e., empty, half-loaded, fully loaded, overloaded) for transport analysis and to monitor changes in industry transport efficiencies.

Other potential enhancements to the WIM+VID data management system will be required as enhancements to WIM sensor/system accuracy evolve to allow for fully automated roadside enforcement.

Office of International programs - FHWA/US DOT (HPIP)

1200 New Jersey Ave., SE

Washington, DC 20590

Tel: (202) 366-9636

Fax: (202) 366-9626

international@fhwa.dot.gov

www.international.fhwa.dot.gov

Publication No. FHWA-PL-07-028 HPIP/10-07(3.5)EW

October 2007