U.S. Department of Transportation

Federal Highway Administration

1200 New Jersey Avenue, SE

Washington, DC 20590

202-366-4000

Ontario requires that the contractor be responsible for the concrete mix design. A minimum concrete compressive strength of 4,350 psi (30 MPa) is required. The coarse aggregate has a combined gradation of nominal maximum size 1.5-in (37.5-mm) and 0.75-in (19-mm) aggregates. The air content is specified as 6.0 percent, plus or minus 1.5 percent. Portland cement is required, but a portion of it may be replaced by supplementary cementitious material. The supplementary cementitious material can be a ground granulated blast furnace slag (up to 25 percent) or fly ash (up to 10 percent) or a combination of the two materials (a mixture of slag and fly ash up to 25 percent except that the amount of fly ash shall not exceed 10 percent by mass of the total cementitious materials).

Québec allows the use of ternary mixes (portland cement, blast furnace slag, and fly ash) in mix designs for CRCP, but not for JPCP. Blended cements are also allowed. For both CRCP and JPCP, a compressive strength of 5,100 psi (35 MPa) is required.

Germany adopted the European concrete standard EN 206-1 in 2000. This standard, together with German standard DIN 1045-2, now constitutes the new German concrete standard. In some areas, the European standard provides only framework definitions, making supplementation by national standards possible and indeed necessary because EN 206 does not yet have the legal status of a harmonized standard in the European Union.(42) One feature of the new standard is an increased emphasis on durability through the use of exposure classes. Roads and bridge decks are in the most extreme exposure class, XF4, characterized by a high degree of water saturation and exposure to freezing and deicing agents. The German concrete standard sets the maximum water-cement ratio (0.50), minimum strength class (C30/37*), minimum cement content (20 lb/ft3 (320 kg/m3)), and minimum air content (4.0 percent) for concrete used in road construction. Beyond the requirements of this standard, the German guideline ZTV Beton-StB 2001, Additional Guidelines for the Construction of Concrete Pavements, sets an upper limit of 0.45 on the water-cement ratio and a minimum cement content of 22 lb/ft3 (350 kg/m3) for paving concrete, as well as a minimum cement content of 26 lb/ft3 (420 kg/m3) for concrete used in an exposed aggregate layer.

The European cement standard EN 197 was adopted at about the same time as the European concrete standard. It defines 27 types of cement. The types of cement to be used for different concrete construction applications are identified in the German standard DIN 1045-2. Among the European standards for cement, aggregate, admixtures, mixing water, etc., so far only the cement standard EN 197 has been adopted as a harmonized standard.

Aggregates must meet the requirements of the European standard EN 12620. Higher standards apply to aggregates for road construction than for aggregates used in buildings and other structures. These include a limit on loss of mass in freeze-thaw resistance testing, limits on the content of lightweight organic contaminants, shape and flakiness index requirements, polished stone value requirements (50 for conventional road surfacing, 53 for exposed aggregate surfacing), and guidelines for mitigating alkali-silica reaction.

Portland cement grade CEM I 32.5 R (equivalent to ASTM Type I), which also has to satisfy additional requirements, is used for concrete paving in Germany.(22,43) With the client's agreement, portland slag cement CEM II /A-2 or CEM II /B-S, portland burnt shale cement CEM II /A-T or B-T, portland limestone cement CEM II /A-LL , or blast furnace cement CEM II /A (at least 42.5 strength class) may also be used.

The cement may not be too finely ground (maximum fineness 3,500 square centimeters per gram (cm2/g)), and must not set for at least 2 hours after placement. In the 1980s, cracking resembling that caused by alkali-aggregate reaction was observed in several pavements between 5 and 10 years old, all built with cements having alkali contents (Na2O equivalent) between 1.0 and 1.4 percent. Since then, only cements with alkali contents less than 1.0 percent have been used for road construction, and these pavements have not exhibited the kind of cracking observed in pavements built earlier. The current German standard limits the alkali content of the CEM I cement to 0.80 percent Na2O equivalent by mass.

Germany has 25 cement-producing groups and plants and 10 concrete pavement contractors. Contractors have responsibility for mix design in Germany and in general the mixes are not proprietary. (Cement products, however, are proprietary.) Fly ash or fillers may be added to the concrete, but fly ash and silica fume may not be used together. Supplementary cementitious materials are not taken into account in the calculation of the cementitious content or the water-cement ratio.

In two-course construction, recycled materials or inexpensive gravels may be used in the lower course, and different strength requirements exist for the upper and lower courses. At least 35 percent of all aggregates must be crushed. High freezing resistance and high resistance to polishing are also required. Germany imports some aggregate from Norway to meet its concrete pavement construction needs.

Concrete in the C30/37 strength class required for road construction must have compressive strength of 4,350 psi (30 MPa) in 6-in-diameter (150-mm-diameter) cores at 60 days, and a compressive strength of 5,400 psi (37 MPa) in 6-in (150-mm) cubes at 28 days. Bending tensile strength is tested only in qualification tests before paving begins. It must be at least 650 psi (4.5 MPa) at 28 days in four-point testing in accordance with EN 12 390-5 (which is nearly identical to a required bending strength of 800 psi (5.5 MPa) tested in accordance with the former DIN 1048 under three-point loading and different test conditions).

Austria's specification for cement and concrete for concrete paving (RVS 8S.06) requires the European standard type CEM II cement, with an initial set time of no less than 2 hours at 68°F (20°C), Blaine fineness no greater than 3,500 cm2/g, and 28-day cube strength no less than 1,000 psi (7 MPa).

Austria's concrete paving specification (RVS 8S.06.32) requires the concrete mix used in the lower course of two-lift construction to have a 28-day flexural strength of at least 800 psi (5.5 M Pa) and a 28-day compressive strength of at least 5,000 psi (35 MPa). The material used in the upper course is required to have a 28-day flexural strength of at least 1,000 psi (7 MPa) and a 28-day compressive strength of at least 5,800 psi (40 MPa).

Concrete mix design is the contractor's responsibility, and the laboratory that the contractor hires can use any method its wants to develop the mix. The contractor's mixture is not considered a proprietary product.

Aggregates used in an exposed aggregate concrete surface layer must have, among other properties, a polished stone value of at least 50. The aggregate used in the lower concrete course may be recycled from old concrete pavement as well as from old asphalt pavement, although the recycled asphalt pavement content is restricted to no more than 10 percent of the total aggregate amount. When an old concrete pavement is recycled, 100 percent of the old pavement is reclaimed, crushed, graded, and reused on site in the new concrete pavement and the cement-treated base, if any.

Portland cement with 20 to 25 percent slag is used in Austria. The minimum cement content for concrete in the lower course is 20 lb/ft3 (320 kg/m3 ) for fixed-form paving and 22 lb/ft3 (350 kg/m3 ) for slipform paving. The minimum cement content for concrete in the upper course is 23 lb/ft3 (370 kg/m3 ) for fixed-form paving, 25 lb/ft3 (400 kg/m3 ) for slipform paving, and 28 lb/ft3 (450 kg/m3 ) for an exposed aggregate layer. An air content of 3.5 to 5.5 percent is required for fixed-form paving and 4.0 to 6.0 percent for slipform paving.

Three types of concrete mixes are used for concrete pavements in Belgium. The cements used are either portland cement (CEM I) or a blast furnace slag cement (CEM III/A) of strength class 42.5, with a limited alkali content to prevent alkali-aggregate reaction. High cement contents, low water-cement ratios, and the use of air entraining agents lead to a very durable, high-strength concrete.

Belgium has not had a problem with alkali-aggregate reaction with its local aggregates, so cements with alkali contents up to 0.9 percent are allowed. Air entraining agents were not used in concrete pavements in Belgium until about 10 years ago.

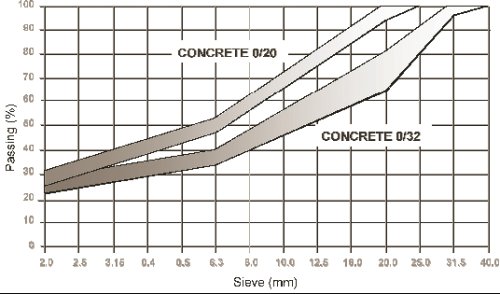

Figure 40 shows gradation curves for aggregates used in concrete pavement mixes in Belgium for maximum aggregate sizes of 20 mm and 32 mm.

Figure 40: Aggregate gradations for concrete paving mixes in Belgium.

Although not stipulated as a requirement, the use of portland fly ash cement (CEM II /B-V 32.5 R, containing 30 to 35 percent fly ash) or portland cement is preferred for concrete pavement construction in the Netherlands. Blended cements containing up to 60 percent slag are also used.

Concrete in the 35/45 strength class is used for concrete paving in the Netherlands. An air-entrained concrete mix with a minimum cement content of 20 lb/ft3 (320 kg/m3) and a water- cement ratio no greater than 0.55 is used. The Netherlands has had no problems with alkali-silica reaction with its local aggregates.

| << Previous | Contents | Next >> |